Phone:

(+65)8319-0742

The integrity of catenary scaffold systems is a non-negotiable aspect of safe and efficient construction sites. Catering to tasks that require flexibility and reach, catenary scaffold setups enable workers to operate securely at substantial heights. Recognizing the inherent risks involved, Catenary Scaffold Safety is an operational priority, ensuring that each temporary aerial work platform not only facilitates productivity but also staunchly protects those who navigate its suspended terrain.

With the extensive use of catenary scaffold in contemporary Catenary Scaffold Construction, comprehensive knowledge and stringent adherence to safety measures cannot be overstated. From meticulous assembly to conscientious disassembly, every stage of scaffold usage underscores the need for unwavering vigilance. As we delve further into the critical components and safety protocols, it’s clear that sustaining high safety standards lies at the heart of this Catenary Scaffold discourse.

Key Takeaways

- The importance of understanding the structure and functionality of catenary scaffold systems in modern construction.

- Recognition of the safety precautions and regulations necessary for operating catenary scaffolds.

- Insights on the crucial role played by catenary scaffolds in reaching challenging areas on construction sites.

- An overview of the strict adherence to OSHA safety standards required for all scaffold operations.

- Exploration of the best practices for the assembly, disassembly, and maintenance of catenary scaffolds.

- The necessity for regular inspections and condition checks to prevent scaffold-related accidents.

Understanding the Basics of Catenary Scaffolds

At the heart of innovative construction methodologies, the Catenary Scaffold System plays a pivotal role in modernizing approach to high-altitude tasks. An intricate network of durable ropes and support mechanisms distinguishes this system from its counterparts, optimizing it for specific, often challenging applications within the construction industry.

Defining Catenary Scaffold Systems

Characterized by their suspension from an overhead structure, catenary scaffold systems exemplify the fusion of Catenary Scaffold Design and functionality. The adaptability of the design allows for various Catenary Scaffold Types that cater to unique project requirements, ranging from lightweight configurations for tasks such as painting or signage installation to more robust structures for heavy-duty work.

Comparing Suspended and Supported Scaffolds

- Suspended Scaffolds: Rely on ropes or chains for support, designed for flexible positioning.

- Supported Scaffolds: Built from the ground up, these provide a stable platform with limited mobility.

The catenary scaffold merges the benefits of suspended systems with the dependability of supported setups, yielding an unrivaled method for working at significant heights.

The Role of Catenary Scaffolds in Modern Construction

Reinventing the reach of the modern construction workforce, the Catenary Scaffold Benefits are manifested in its ability to provide access to otherwise inaccessible areas. This is particularly advantageous when dealing with high-rise structures or complex architectural elements where traditional scaffolds fail to suffice.

Inherent to its design advantages, the catenary scaffold adapts to the contours of modern construction sites, demonstrating notable manageability and reliability.

The comparative advantages of various scaffold systems are outlined in the table below, underscoring why the catenary scaffold system is often the preferred choice for modern construction scenarios:

| Scaffold Type | Design Flexibility | Mobility | Suitability for High-Rise Applications | Usage in Complex Constructions |

|---|---|---|---|---|

| Catenary Scaffold | High | Medium to High | Excellent | Excellent |

| Supported Scaffold | Moderate | Low | Good | Moderate |

| Suspended Scaffold | High | High | Good | Good |

As seen, catenary scaffolds are notably superior in their ability to fulfill the dynamic demands of modern construction, marking them as an essential component in the array of construction solutions.

Key Components of a Catenary Scaffold

When it comes to Catenary Scaffold Installation, understanding the critical nature of the individual Catenary Scaffold Components is essential for the safety and functionality of the structure. Each element must satisfy rigorous safety standards to offer a reliable work platform for construction professionals.

The foundational Catenary Scaffold Components include a mix of horizontal and vertical ropes which are typically composed of highly durable materials such as wire or synthetic fibers. These ropes are held to high standards that go beyond bearing just the weight of workers and their tools; they incorporate additional safety margins to ensure peace of mind and risk mitigation at elevated heights.

Moreover, the installation process of a catenary scaffold hinges on the usage of robust connectors and ties. These fittings not only secure the ropes in place but also stabilize the platform, making the crucial link between safety and structural integrity. To ensure this, every component must be methodically selected and tested as part of the Catenary Scaffold Installation process.

| Component | Material Used | Function | Safety Consideration |

|---|---|---|---|

| Horizontal Ropes | Synthetic Fibers / Wire | Supports platform along length | Must support intended load with safety margin |

| Vertical Ropes | Wire | Supports platform from above | Requires inspection for wear and damage |

| Connectors and Ties | Steel / Aluminum Alloys | Stabilizes platform, anchors ropes | Corrosion-resistant, capable of withstanding dynamic loads |

| Platform | Wood / Metal Composites | Area for workers and tools | Non-slip surface, structurally sound for set capacities |

Without overlooking the importance of each scaffold part, it is the cohesive assembly and the cumulative strength of all Catenary Scaffold Components that craft a secure working environment. By factoring in every tool and material used in the Catenary Scaffold Installation, professionals reinforce their commitment to uncompromising safety and meticulous planning on the job.

- Selection of ropes designed for their purpose and checked for integrity

- Installation of connectors and ties performed with precision

- Assembled platform rigorously evaluated for stability and resilience

In essence, every piece of a catenary scaffold plays an indispensable role. As a convergence of material science and engineering expertise, this scaffold type paves the way for safe and efficient construction at impressive heights.

Installation and Setup of Catenary Scaffold Systems

Embarking on the installation of a catenary scaffold system is a process that demands meticulous attention, both to catenary scaffold safety protocols and to the particularities of the project in question. Fundamental to the success and security of this installation is the assimilation of a structured, step-by-step approach that encompasses site assessment, adherence to a pre-installation checklist, and a keen understanding of the system’s assembly.

Site Assessment and Pre-Installation Checklist

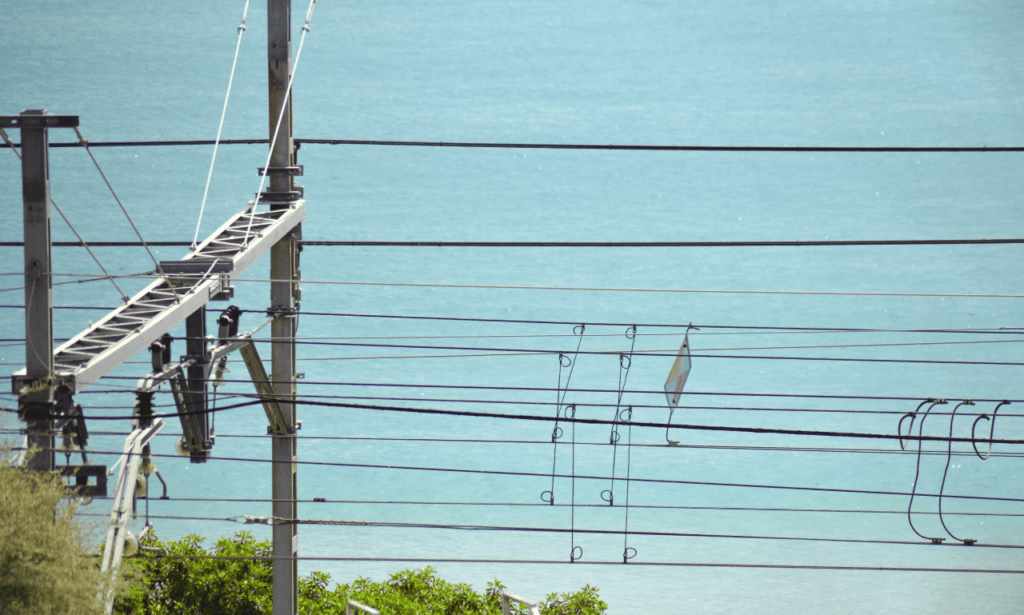

Prior to the erection of any catenary scaffold types, a comprehensive site assessment must be performed. This ensures that the designated area is free from potential hazards and can securely support the scaffold installation. Elements such as power lines, ground stability, and weather conditions are evaluated. Concurrently, a pre-installation checklist helps in affirming the readiness of all equipment and the structural integrity of the scaffold’s attachment points.

Step-by-Step Guide to Safely Erecting Catenary Scaffolds

A precise and measured guide assists in erecting catenary scaffolds safely. This includes outlining the necessary sequence of actions, from securing sturdy tiebacks to anchorage points, to ensuring the ropes are tensioned correctly, thereby maximizing the catenary scaffold benefits of safety and flexibility. The guidance of a competent individual is vital throughout this process, as is a thorough understanding of the scaffold’s weight capacity.

Common Installation Challenges and Solutions

Installation challenges such as complex designs spanning multiple levels or adverse environmental conditions can impact the safe setup of catenary scaffolds. Tailoring scaffold designs to particular project requirements is often a necessary step, and necessitates agile problem-solving strategies. Solutions emphasize the critical nature of regular inspections, carefully staged installations, and commitment to industry standards set out by safety regulations.

Ultimately, the effective installation and application of catenary scaffolds can only be achieved through a systematic approach that covers every aspect of preparation and assembly. This ensures that the benefits of such structures are fully realized, thereby contributing to the efficacy and success of various construction projects.

Catenary Scaffold Safety Regulations and Best Practices

The meticulous construction and utilization of catenary scaffold systems are governed by an array of safety regulations and industry best practices. These guidelines are designed to ensure that every catenary scaffold construction offers the utmost in safety benefits and adheres to professional design standards.

Understanding OSHA Scaffolding Safety Requirements

The Occupational Safety and Health Administration (OSHA) has established comprehensive requirements for catenary scaffolds, necessitating a safety-first approach in their construction and use. Notably, catenary scaffold construction must accommodate a minimum of four times the maximum predicted load, providing a robust assurance of structural integrity.

Implementing Fall Protection and Prevention Measures

One of the paramount catenary scaffold benefits is the incorporation of fall protection systems that safeguard workers operating at heights. Appropriate fall prevention measures, such as sturdy guardrails and dependable personal fall arrest systems, are mandate for any scaffold platforms situated more than 10 feet above lower levels.

Maintaining and Inspecting Catenary Scaffolding

Integral to the lasting efficacy of catenary scaffold design is the commitment to ongoing maintenance and inspection practices. These critical examinations, conducted by qualified personnel, ensure each component of the scaffold remains free of damage, thereby extending its reliable service life and functionality.

| Safety Feature | Benefit | Inspection Frequency |

|---|---|---|

| Load Capacity | Ensures structural support | Before each shift and after any incident |

| Guardrails | Prevents falls | Before work begins and periodically thereafter |

| Fall Arrest Equipment | Provides secondary form of fall protection | Before each use |

| Platform Integrity | Maintains a secure working surface | At setup, alteration, and dismantling |

Adhering to these regulatory measures and maintaining a vigilant approach to safety can enhance the positive outcomes associated with catenary scaffold utilization in various construction projects.

Diverse Applications of Catenary Scaffold in Construction

The versatility of catenary scaffold types illustrates a range of catenary scaffold benefits, particularly their adaptability to various environments and tasks. From the sleek facades of urban skyscrapers to the sprawling expanses of industrial complexes, these systems are utilized extensively to provide secure, elevated work platforms.

Catenary Scaffold Safety is at the forefront of their design, meaning workers can depend on these structures even when completing tasks at great heights or above sensitive areas. These systems ensure efficient access while maintaining the utmost levels of protection for the workforce, as every component, from cables to platforms, adheres to rigorous safety standards.

Below, explore the diverse applications of catenary scaffolds, demonstrating their indispensable role in construction and maintenance.

- Exterior Building Maintenance: Facilitating tasks such as window cleaning, facade restoration, and painting.

- Structural Inspections: Enabling thorough inspections of bridges, towers, and historical monuments.

- Entertainment Venues: Assisting in the setup and disassembly of stage designs and lighting systems for events.

- Retail Settings: Offering support for signage installation and exterior decoration across storefronts and shopping centers.

Safeguarding worker safety while providing the required flexibility, catenary scaffold components must always be carefully selected and compliant with industry standards. The proper match of scaffold type to the job requirements is pivotal in achieving operational efficiency and ensuring that the structure operates within its intended safety parameters.

| Environment | Use Case | Preferred Scaffold Type |

|---|---|---|

| High-Rise Buildings | Window Cleaning/Maintenance | Flexible Suspension Scaffold |

| Industrial Facilities | Structural Work | Heavy-Duty Catenary Scaffold |

| Historical Sites | Restoration and Inspection | Custom-Configured Scaffold |

| Entertainment Arenas | Stage Design and Lighting | Modular Suspended Scaffold |

For every unique application, the catenary scaffold benefits are evident in the productivity and security they provide. Professionals across the construction and maintenance industries recognize the significant advantages that these innovative systems bring to their work.

Conclusion

In sum, the efficacy and resilience of the Catenary Scaffold System cannot be understated within the realm of contemporary construction. Through a thorough understanding of its framework, spanning from meticulous Catenary Scaffold Design to the precision-driven Catenary Scaffold Installation process, professionals in the field can take advantage of its flexibility and safety. This type of scaffold system is instrumental in providing secure, accessible, and productive work environments at considerable heightsâan undebatable necessity in the evolving landscape of structural development.

Strict adherence to OSHA safety regulations garners a workspace where the hazards of elevated construction are significantly mitigated. The practice of integrating scaffold safety into the foundational training of construction workers underpins the commitment to optimizing worksite conditions. This dedication ensures not only the protection of personnel but also the integrity and success of the projects they undertake. As such, the adoption of catenary scaffolds signals an allegiance to upholding the highest standards of occupational safety and project excellence.

Finally, the unparalleled adaptability and application range of the catenary scaffold align seamlessly with the dynamic demands of modern construction projects. It underlines a forward-thinking approach to architectural endeavors, where the safety and welfare of the workforce remain the keystone. Moving forward, as the scope of construction continues to expand, the emphasis on up-to-date scaffold training and stringent regulatory compliance is expected to ascend in parallel, reinforcing a commitment to both the progression of construction methodologies and the steadfast safeguarding of human life.

FAQ

What is a catenary scaffold?

A catenary scaffold is a type of suspended scaffold system primarily used in construction. It is supported by multiple ropes attached to a secure overhead structure, from which a work platform is suspended. This design allows workers to access high elevations and hard-to-reach areas safely.

How is a catenary scaffold different from traditional supported scaffolds?

Unlike supported scaffolds, which rely on rigid supports from the ground, catenary scaffolds are suspended by ropes or wires and rely on the strength of these ropes and the stability of the overhead structure for support. This design allows for more flexibility and accessibility in various construction scenarios.

What are the benefits of using catenary scaffolds in modern construction?

Catenary scaffolds provide significant benefits by enabling workers to safely reach difficult areas that might be inaccessible with traditional scaffolding. They are versatile, adaptable, and offer maneuverability for tasks such as window cleaning, painting, and building maintenance on high-rise structures.

What are the key components of a catenary scaffold?

The key components include horizontal and vertical ropes, connectors, and a stable work platform. These elements are crucial for the safety and functionality of the scaffold and must be carefully selected, tested, and installed to meet specific load requirements and safety standards.

What is involved in the installation of a catenary scaffold system?

Installation begins with a thorough site assessment to address potential hazards. A pre-installation checklist is crucial for confirming that the overhead structure and ropes can safely support the intended load. The erection of the scaffold includes securing tiebacks, ensuring proper rope tension, and is supervised by a competent person throughout the process.

What are the common installation challenges with catenary scaffolds and how are they addressed?

Installation challenges may involve dealing with multiple levels, environmental factors affecting rope stability, and the need for customized designs. These are addressed through careful planning, regular inspections, and strict adherence to safety regulations set by authorities like OSHA.

What safety regulations must catenary scaffolds comply with?

Catenary scaffolds must comply with OSHA regulations, which include the requirement that scaffolding support at least four times the maximum intended load. Suspension ropes should support six times the intended load. Fall protection measures must be in place for elevations over 10 feet, and routine inspections by competent individuals are mandatory to maintain the structure’s integrity.

How are fall protection and prevention measures implemented in catenary scaffolds?

Fall protection includes guardrails and personal fall arrest systems for heights over 10 feet. The scaffold must also have mechanisms for fall prevention, such as toe boards and debris nets, to protect workers on the scaffold and individuals below from potential falling objects.

Why is it crucial to maintain and inspect catenary scaffolding regularly?

Regular maintenance and inspection are critical to ensure the safety and structural integrity of catenary scaffolding. These practices help identify damages or wear that could compromise safety, verify that components are correctly installed, and ensure compliance with scaffolding safety requirements.

In what industries are catenary scaffolds commonly used?

Catenary scaffolds are widely used in the construction industry, particularly for work on high-rise buildings. However, their applications also extend to window cleaning, exterior building maintenance, painting, and sometimes in entertainment or retail settings where access to elevated heights is required.

Safe Scaffolding Training Programs & Courses

In the realm of construction, scaffolding stands as a fundamental fixtureâessential for countless projects…

Fraco Scaffold: Innovative Construction Solutions

Fraco is a top name in the construction world, known for its fraco scaffolding and building materials….

Scaffolding System Essentials for Construction Safety

The significance of a robust scaffolding system in ensuring construction safety can hardly be understated….

Choosing the Right Scaffolding Size for Your Project

Selecting the correct Scaffolding Size can determine the success, safety, and efficiency of your construction…

Facade Access Scaffolding Solutions Expert

When undertaking complex high-rise projects, the integration of facade access scaffolding solutions is…

No posts found