Phone:

(+65)8319-0742

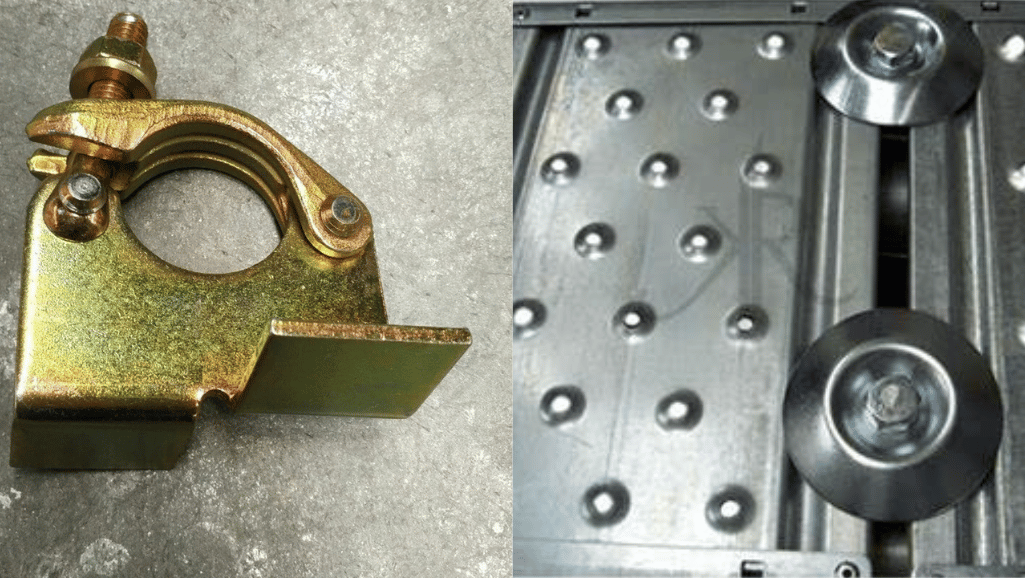

Board clamp scaffolding, also known as scaffold board clamps or battens clamps, plays a pivotal role in ensuring safety and efficiency on construction sites. These clamps are used to secure scaffold boards firmly, preventing them from shifting or slipping under the load of workers and materials. This stability is crucial for maintaining a safe work environment and preventing accidents., it’s important to choose the right ones for your specific needs. In this article, we will explore the different types of board clamps and provide recommendations for the best selections based on factual data and expert advice.

Key Takeaways:

- Critical Safety Component: Board clamps are vital in maintaining a stable and secure work environment on scaffolding. They prevent scaffold boards from shifting or slipping, which is crucial for preventing accidents and ensuring worker safety.

- Durable Materials: Board clamps are typically made from strong, corrosion-resistant materials like galvanized steel or aluminum. This ensures longevity and reliability even under harsh construction conditions.

- Ease of Use: These clamps are designed for easy installation and removal, allowing for quick adjustments without specialized tools. This feature enhances the efficiency of construction workflows and facilitates rapid response to changing conditions on the site.

- Compliance with Standards: Adhering to regulatory standards, such as those set by OSHA in the United States, is mandatory. These standards ensure that the clamps can support the required loads and function safely under various conditions.

- Enhances Structural Stability: By securing scaffold boards tightly, board clamps contribute to the overall stability of the scaffolding structure. This is particularly important in preventing collapses under heavy loads or during adverse weather conditions.

- Versatile Application: Board clamp scaffolding can be used across a broad spectrum of construction projects, from small residential repairs to large-scale commercial buildings. This versatility makes them an indispensable tool in the construction industry.

Parallel-Jaw Clamps (K-Body Clamps) for Versatile Woodworking Projects

Fundamental Role in Scaffold Safety Board clamps serve as an integral part of scaffolding systems, primarily designed to secure scaffold boards in place. Scaffold boards are the horizontal platforms on which workers stand and move, and their stability is paramount for safety. Board clamps lock these boards together, preventing any lateral or vertical movement that could lead to unsafe working conditions.

Preventing Board Movement The key functionality of board clamps is to clamp scaffold boards tightly against each other and the scaffolding structure. This is crucial because any movement of these boards can create gaps or cause the boards to overlap unsafely, both of which are common tripping hazards. Trips and falls from even low heights can result in serious injuries; thus, ensuring that boards are immobile is essential.

Enhanced Structural Integrity By firmly securing the boards, board clamps not only prevent accidents caused by slips and trips but also contribute to the overall structural integrity of the scaffolding. A scaffold with tightly clamped boards is more resistant to shifting under weight or in windy conditions, which enhances safety for workers and stability for the materials and tools placed on the scaffold.

Mitigating Risk of Accidents The prevention of board slippage is especially important in environments where workers carry heavy loads or move dynamically across the scaffold. Unsecured boards could shift under such stress, leading to potential falls and dropped objects, which are hazardous for everyone on the site. Board clamps mitigate these risks by ensuring that each board is firmly anchored in relation to its neighboring boards and the scaffold structure.

Regulatory Compliance Regulatory bodies around the world recognize the importance of secure scaffolding. Compliance with safety standards often explicitly requires that all components of a scaffolding system, including board clamps, be checked regularly for secure fitting and wear and tear. Non-compliance not only poses safety risks but also legal repercussions for construction firms.

Safety During High Impact Activities In construction projects where heavy machinery or vigorous activities such as hammering or drilling are involved, the vibration transmitted through the scaffold can dislodge unsecured boards. Board clamps play a crucial role in these scenarios by absorbing and mitigating the impact, thus maintaining a stable platform.

| Aspect | Durable Materials | Scaffold Board Clamps |

|---|

| Material Composition | Typically made from metals like steel or aluminum for high strength and corrosion resistance. | Often made from galvanized steel or aluminum to resist corrosion and ensure longevity under rigorous use. |

| Purpose | Chosen for their ability to withstand environmental stresses, loads, and extended use without degradation. | Specifically designed to securely fasten scaffold boards, preventing movement and ensuring a stable platform. |

| Usage | Used broadly in construction for structural supports, beams, frames, and hardware. | Used specifically in scaffolding systems to lock scaffold boards in place, crucial for safety and stability. |

| Benefits | Longevity, reliability, and minimal maintenance under normal conditions. | Provides critical safety by preventing board slippage, which can lead to falls and injuries. |

| Adaptability | Materials can be used across various applications and industries, not limited to construction. | Primarily used in scaffolding, with a specialized design tailored to fit standard scaffold board thicknesses. |

| Maintenance | Durable materials generally require less frequent maintenance but should be inspected regularly in construction settings. | Requires regular checks for secure fitting and potential damage from use, important for maintaining safety standards. |

| Cost | Often more expensive initially due to quality and durability factors, but cost-effective over time due to less frequent replacement needs. | Cost varies based on brand and quality, but essential for safety, thus non-negotiable in terms of procurement and use in scaffolding. |

Board Clamps for scaffolding Projects

Bar clamps, particularly iron bar clamps with a saw-tooth pattern on the jaw, are excellent for heavy-duty woodworking tasks. These clamps provide the necessary strength and stability for tackling large projects such as gluing up workbench tops and creating bending jigs. Unlike K-body clamps, bar clamps can exert more pressure, making them indispensable for projects that require extra force.

While bar clamps can certainly be used for smaller work, their weight makes them less convenient compared to K-body clamps. However, when it comes to heavy-duty tasks, bar clamps are highly reliable and effective. Their sturdy construction ensures durability and longevity, making them a valuable addition to any woodworking shop.

In addition to iron bar clamps, there are also aluminum bar clamps available in the market. These clamps possess the advantage of being lightweight, but they may require additional strengthening to prevent bending during heavy-duty projects.

To get the most out of your woodworking endeavors, it is highly recommended to build a collection of both K-body clamps and vintage iron bar clamps. This combination will offer versatility and coverage for a wide range of woodworking needs, allowing you to achieve professional results every time.

When selecting iron bar clamps, look for those with a saw-tooth pattern on the jaw. This feature enhances gripping power, ensuring a secure hold on the workpiece. Vintage iron bar clamps are particularly sought-after for their superior performance and craftsmanship.

In summary, bar clamps, especially iron bar clamps, are essential tools for heavy-duty woodworking projects. Their strength, stability, and durability make them invaluable for tasks such as gluing up workbench tops and creating bending jigs. By incorporating bar clamps into your woodworking collection alongside K-body clamps, you can confidently undertake a variety of projects with precision and success.

Pipe Clamps for Affordable and Convenient Clamping

Pipe clamps are a cost-effective option for clamping in woodworking projects. While these clamps may have small jaws and be on the heavier side, their affordability makes them attractive for both beginners and professionals. They are particularly useful for large-scale work and house renovation projects.

Benefits of Pipe Clamps

- Pipe clamps are inexpensive clamps that provide a sturdy grip on your workpieces.

- They are versatile and can be used in various woodworking applications.

- These clamps are especially useful when long clamps are required.

When using pipe clamps, it is recommended to use 3/4-inch diameter pipes as they offer greater rigidity compared to 1/2-inch pipes. This is especially important when working on larger projects that require more pressure.

To protect your workpiece from damage, consider adding rubber pads or epoxy to the jaws of the pipe clamp. This will prevent the metal jaws from leaving marks or indentations on the wood surface.

It’s important to note that pipe clamps made of raw iron may stain the workpiece, particularly if it is made of oak or other porous woods. To avoid potential staining, consider using clamps with coated or plastic jaws for these types of materials.

Comparison of Pipe Clamp Options

| Clamp Type | Material | Jaw Size | Cost |

|---|---|---|---|

| Pipe Clamps | Raw Iron | 2-1/2 inches | Inexpensive |

| Pipe Clamps (with rubber pads) | Raw Iron | 2-1/2 inches | Slightly higher cost |

| Coated Pipe Clamps | Coated steel | 2-1/2 inches | Higher cost |

When selecting pipe clamps, consider your budget as well as the specific requirements of your woodworking projects. Coated pipe clamps may be a better option if you’re concerned about potential staining or want a more durable clamp with a higher resistance to rust.

Overall, pipe clamps offer an affordable and convenient clamping solution for woodworking projects. Their versatility, low cost, and ability to handle large-scale work make them a valuable addition to any woodworker’s toolkit.

F-Style Clamps for Versatile Woodworking Projects

When it comes to securing workpieces in woodworking projects, F-style clamps are a popular choice in woodworking shops. These clamps feature a long handle and two adjustable metal jaws, allowing for easy adjustment to fit the thickness of the wood. Their versatility makes them suitable for various projects, including assembling smaller pieces and gluing up small workpieces.

One of the advantages of F-style clamps is their compatibility with angled clamping blocks. By adding angled clamping blocks to the clamp, woodworkers can efficiently glue up and clamp different angles in their projects. This feature opens up a world of possibilities for creating intricate designs and ensuring precise alignment.

Additionally, F-style clamps are generally affordable, making them a cost-effective option for woodworkers. They can be built up in a collection, allowing for faster work during larger projects.

Benefits of F-Style Clamps:

- Secure workpieces with adjustable metal jaws

- Versatile for various woodworking projects

- Compatible with angled clamping blocks for gluing different angles

- Affordable option for woodworkers

Recommended F-Style Clamps:

| Brand | Key Features |

|---|---|

| Bessey F-Style Clamps | – Durable construction |

| IRWIN QUICK-GRIP Clamps | – Quick-release mechanism for ease of use |

| Jorgensen Steel Bar Clamps | – Heavy-duty design |

Investing in a quality set of F-style clamps will enhance your woodworking capabilities. Whether you’re working on small projects or require precise angle clamping, these clamps are a valuable addition to any workshop.

Conclusion

In conclusion, selecting the right board clamps is essential for achieving secure and precise woodworking. Based on factual data and expert advice, parallel-jaw clamps (K-body clamps), bar clamps, pipe clamps, hand screws, F-style clamps, and other specialized clamps are recommended for different woodworking tasks.

It is important to consider the specific needs of your woodworking projects and build a versatile collection of clamps that will serve you well in achieving professional results. With the right board clamps, you can ensure a solid grip and precise alignment, making your woodworking projects a success.

FAQ

What are board clamps?

Board clamps are tools used in woodworking to provide a secure grip and precise alignment of workpieces.

Why are board clamps important in woodworking?

Board clamps are essential in woodworking because they ensure a solid grip and precise alignment, leading to professional results.

What are parallel-jaw clamps?

Parallel-jaw clamps, also known as K-body clamps, are versatile clamps that are commonly used in woodworking shops. They feature large jaws that can apply pressure to specific points for gluing up dovetails and panel glue-ups.

Which brands of parallel-jaw clamps are recommended?

Recommended brands of parallel-jaw clamps include Bessey and Jet, both known for their quality and durability. Bessey clamps have wood handles, while Jet clamps have faceted handles, providing different gripping options.

What are bar clamps used for?

Bar clamps, particularly iron bar clamps with a saw-tooth pattern on the jaw, are excellent for heavy-duty woodworking tasks such as gluing up workbench tops.

What types of bar clamps are available?

Iron bar clamps and aluminum bar clamps are the two common types available. Iron bar clamps are recommended for their durability, while aluminum bar clamps may require additional strengthening to prevent bending.

What are pipe clamps used for?

Pipe clamps are affordable options for clamping in woodworking projects. They are useful for situations where long clamps are required, such as house renovation work.

What diameter pipes should be used with pipe clamps?

It is recommended to use 3/4-inch diameter pipes with pipe clamps, as 1/2-inch pipes may not be rigid enough for larger projects.

What are hand screws used for in woodworking?

Hand screws are versatile clamps used in woodworking shops for various tasks, including functioning as vises and holding odd-shaped workpieces.

What sizes of hand screws are recommended?

Larger sizes of hand screws are the most useful for woodworking tasks, as they provide optimal performance and versatility.

What are F-style clamps used for?

F-style clamps are commonly used in woodworking shops for securing workpieces to the bench. They are versatile and can be used for various projects, including assembling smaller projects and gluing up small workpieces.