Phone:

(+65)8319-0742

When it comes to construction projects, the importance of base plates and sole boards cannot be overstated. These crucial components play a vital role in providing structural integrity, stability, and support to the overall construction. Whether you’re building a residential home, a commercial complex, or an industrial facility, understanding the significance of base plates and sole boards is essential.

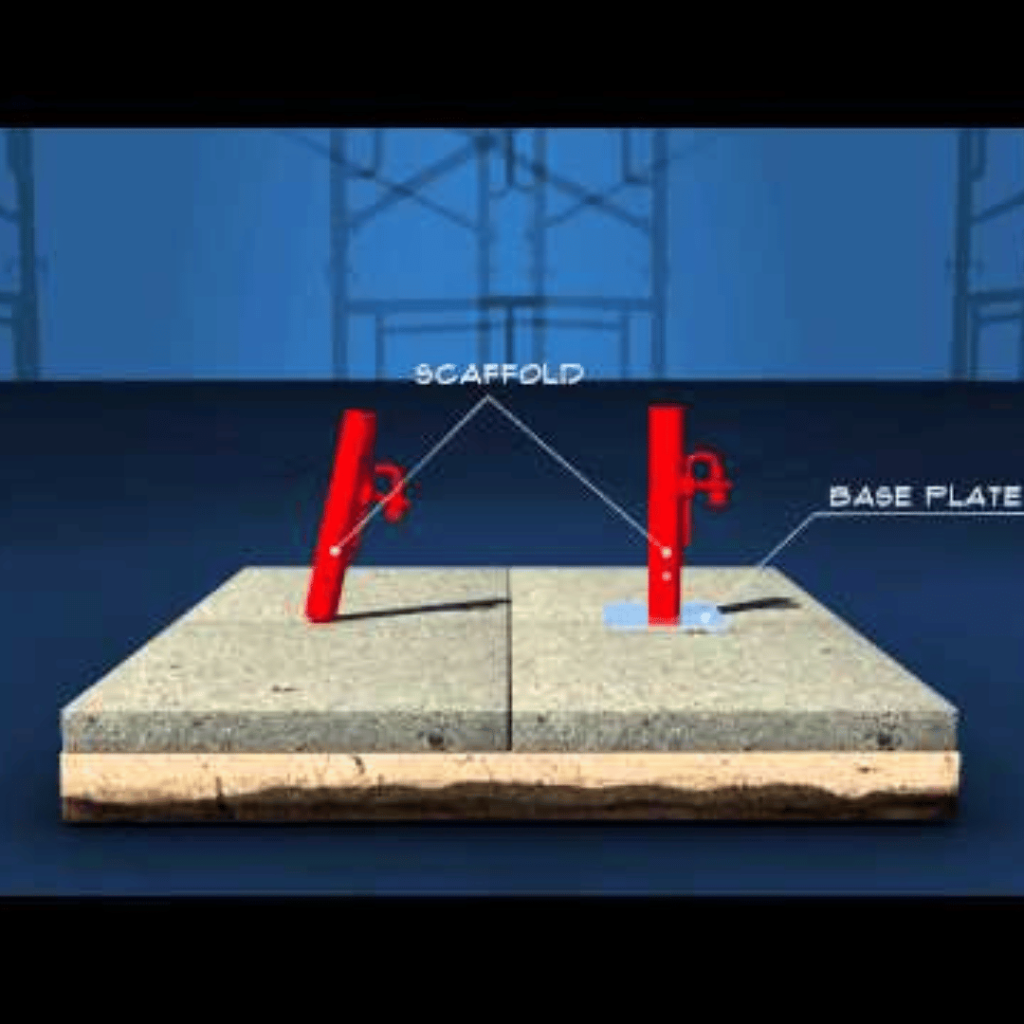

Base plates serve as the foundation for the entire structure, providing a sturdy base for the vertical supports. They distribute the weight and load of the building evenly, ensuring stability and preventing settling or shifting. Sole boards, on the other hand, act as a protective layer between the foundation and the structure. They provide an additional level of support, helping to distribute the weight and minimize any potential damage caused by moisture or ground movement.

Both base plates and sole boards are typically made from durable materials such as wood or engineered materials. Wooden sole boards are commonly used in construction due to their strength, affordability, and ease of installation. Engineered sole boards, on the other hand, offer enhanced durability and resistance to moisture, making them ideal for areas with high humidity or frequent exposure to water.

Proper installation and maintenance of base plates and sole boards are crucial for their long-term performance. It’s important to follow the recommended guidelines and ensure that the components are securely fastened and aligned. Regular inspection and maintenance are also essential to identify any issues early on and address them promptly.

Choosing high-quality base plates and sole boards is of utmost importance for construction projects. Investing in reliable materials will ensure the structural integrity and longevity of the building. Substandard or compromised products can lead to a host of issues, including structural instability, excessive settling, and potential safety hazards.

Key Takeaways:

- Base plates and sole boards play a crucial role in providing structural integrity and support in construction projects.

- Base plates serve as the foundation for the structure, while sole boards act as a protective layer between the foundation and the building.

- Both wooden and engineered sole boards are commonly used in construction, each offering their own advantages.

- Proper installation and maintenance are essential for the long-term performance of base plates and sole boards.

- Investing in high-quality base plates and sole boards is essential to ensure the stability and longevity of the building.

Understanding Base Plate in Construction

In the world of construction, base plates play a vital role in ensuring the stability, durability, and overall structural integrity of buildings and various structures. These essential components act as the foundation base plate, providing a secure and supportive connection between the structure and the ground. Whether it’s a small residential project or a massive commercial construction, understanding the importance of base plates is crucial for successful and long-lasting outcomes.

Base plates, also known as construction base plates, serve as the interface between the foundation and the superstructure. They distribute the vertical and horizontal loads transmitted by the building to the substructure, ensuring uniform weight distribution and preventing excessive stress concentration at localized points. In addition to bearing the weight of the structure, base plates also provide a stable surface for structural support, anchoring, and stability.

When it comes to base plate materials, several options are available in the market. The selection primarily depends on factors such as the type of construction, the load requirements, and the environmental conditions. Common materials used for base plates include steel, concrete, and composite materials. Steel base plates are favored for their strength, durability, and ease of installation. Concrete base plates, on the other hand, offer excellent load-bearing capacity and are ideal for heavy-duty applications. Composite base plates combine the benefits of both steel and concrete, providing a cost-effective solution without compromising on strength or durability.

Let’s explore the different types of base plates commonly used in construction:

- Rectangular Base Plate: This type of base plate features a rectangular shape and is widely utilized in various construction projects. It provides a stable foundation and evenly distributes the load, ensuring optimal structural support.

- Circular Base Plate: Circular base plates are typically used in applications where rotational forces need to be transmitted evenly. They are commonly employed in the construction of towers, poles, and columns.

- Skewed Base Plate: Skewed base plates are designed to accommodate structures with non-standard angles or irregular shapes. They provide stability and support in situations where a traditional rectangular or circular base plate may not be suitable.

Proper installation of base plates is critical to ensure their effectiveness and long-term performance. It involves precise alignment, secure anchoring, and appropriate load distribution. Working with experienced professionals and adhering to industry standards in base plate installation is vital for maintaining structural integrity and preventing potential failures. Regular inspection and maintenance, including monitoring for signs of wear or damage, are also essential to ensure the ongoing stability and safety of the structure.

| Material | Pros | Cons |

|---|---|---|

| Steel | Durable, strong, easy to install | Prone to corrosion if not properly coated |

| Concrete | Excellent load-bearing capacity, suitable for heavy-duty applications | Requires more time and effort for installation |

| Composite | Cost-effective, combines strength and durability | May have limitations in extreme environmental conditions |

Base plates are an integral part of the construction process, providing the foundation and structural support necessary for the successful completion of any project. From ensuring stability and load distribution to withstanding environmental factors, base plates play a crucial role in the long-term durability and safety of structures. By understanding the different types and materials available, as well as following proper installation and maintenance practices, construction professionals can confidently incorporate base plates into their projects, setting the groundwork for reliable and resilient structures.

Exploring Sole Boards in Construction

Sole boards play a crucial role in construction projects, providing essential structural support and stability. Let’s delve deeper into the world of sole boards and discover the different types available, including wooden and engineered options.

Types of Sole Boards

When it comes to sole boards, there are two primary options to consider:

- Wooden Sole Boards: Known for their traditional appeal and durability, wooden sole boards are widely used in construction. They offer excellent strength and stability, making them ideal for both residential and commercial projects. Wood’s natural properties help dampen vibrations and reduce noise, contributing to a comfortable and peaceful environment.

- Engineered Sole Boards: Engineered sole boards are a modern alternative to traditional wooden boards. They are constructed by layering wood veneers or particles together with a strong adhesive, resulting in a highly stable and reliable product. Engineered sole boards offer enhanced dimensional stability, making them resistant to warping, shrinking, or expanding due to changes in temperature or humidity.

Functions and Benefits

Sole boards serve multiple functions in construction and provide several benefits:

- Structural Support: Sole boards distribute the load of the structure evenly, transferring the weight to the foundation. They provide a solid base for floors and walls, ensuring stability and preventing sagging or settlement issues.

- Enhanced Strength: By acting as a structural element, sole boards increase the overall strength of the construction. They help minimize deflection and ensure the longevity of the building.

- Noise Reduction: Wooden sole boards effectively reduce impact noise by absorbing vibrations. This quality is particularly valuable in multi-story buildings or areas where noise control is essential.

- Easy Installation: Both wooden and engineered sole boards are relatively easy to install. They are typically laid on top of the base plate or joists, providing a level surface for the subsequent layers of construction.

When choosing the right sole board material for your construction project, consider factors such as the intended use, load requirements, budget, and environmental considerations. Consulting with a professional or structural engineer can help you make an informed decision.

To visualize the differences between wooden and engineered sole boards, take a look at the comparison table below:

| Wooden Sole Boards | Engineered Sole Boards |

|---|---|

| Traditional appeal | Modern alternative |

| Highly durable | Dimensionally stable |

| Excellent strength | Resistant to warping and shrinking |

| Good noise absorption | Reduced risk of moisture-related issues |

Base Plates vs. Sole Boards: Key Differences

When it comes to construction, base plates and sole boards play crucial roles in providing structural support and stability. While they serve similar purposes, there are distinct differences between these two components, making them suitable for different applications. Understanding these differences is essential for selecting the right option for specific construction scenarios.

Base plates are flat plates made of robust materials such as steel or concrete. They are designed to distribute the load evenly and act as a foundation base plate for different structures. Base plates are commonly used in large-scale construction projects where heavy machinery or equipment is involved. These plates provide a stable platform and protect the underlying structure from excessive stresses and settling.

Sole boards, on the other hand, are structural elements typically made of wood or engineered materials. They are used as a form of temporary or permanent support for beams, columns, or walls during construction. Sole boards are versatile, cost-effective, and easy to work with, making them ideal for various construction applications. They offer stability and help distribute the load, ensuring the structural integrity of the project.

To better understand the differences between base plates and sole boards, let’s compare their distinct characteristics:

- Material: Base plates are primarily made of sturdy materials like steel or concrete, providing exceptional strength and durability. Sole boards, on the other hand, are commonly constructed using wood or engineered materials, offering flexibility and cost-effectiveness.

- Function: Base plates act as a foundation base plate, providing a solid and level surface for vertical structures. They distribute the load and anchor the structure securely to the ground. Sole boards, on the other hand, offer temporary or permanent support during construction, ensuring the stability of beams, columns, or walls.

- Application: Base plates are commonly used in large-scale construction projects, such as high-rise buildings or bridges, where heavy loads and machinery are involved. Sole boards are versatile and are often used in various construction scenarios, including residential, commercial, and industrial projects.

Choosing between base plates and sole boards depends on the specific requirements of your construction project. While base plates offer robust support for heavy loads and machinery, sole boards are more versatile and cost-effective for temporary support during construction. It’s crucial to assess the structural needs, load-bearing capacity, and long-term considerations to determine which option is best suited for your construction project.

As construction experts, we understand the importance of selecting the right building materials and components for your project. With a wide range of base plates and sole boards available in the market, you can find the perfect solution to ensure structural integrity and support throughout the construction process and beyond.

Installation and Maintenance of Base Plates and Sole Boards

Proper installation and regular maintenance are crucial for ensuring the effectiveness and longevity of base plates and sole boards in construction projects. By following the recommended procedures and implementing appropriate care techniques, you can enhance the structural support provided by these essential building materials. This section will guide you through the step-by-step installation process and provide valuable maintenance tips to maximize the performance of your base plates and sole boards.

Installation Process:

- Start by preparing the construction site and ensuring a stable and level foundation.

- Choose the appropriate base plate or sole board material based on the specific requirements of your project.

- Position the base plates or sole boards securely in their designated locations, using appropriate fasteners or adhesives.

- Ensure proper alignment and levelness of the base plates or sole boards to maintain structural integrity.

- Follow manufacturer instructions for any additional installation steps specific to the chosen base plate or sole board.

Remember to prioritize safety measures during the installation process. Use protective equipment and follow all recommended guidelines to minimize the risk of accidents or injuries.

Maintenance Tips:

To prolong the lifespan of base plates and sole boards, regular maintenance is essential. Follow these tips for proper upkeep:

- Regularly inspect the base plates and sole boards for any signs of damage, such as cracks, warping, or decay.

- Address any identified issues promptly to prevent further deterioration.

- Ensure proper drainage around the base plates and sole boards to prevent water accumulation and potential damage.

- Regularly clean the surfaces of base plates and sole boards to remove dirt, debris, and any substances that may compromise their performance.

- Apply appropriate protective coatings or treatments to enhance the durability and resistance of the base plates and sole boards.

By following these installation and maintenance practices, you can optimize the structural support and longevity of your base plates and sole boards, ensuring the success of your construction project.

| Benefit | Installation | Maintenance |

|---|---|---|

| Enhanced Structural Support | Proper installation techniques ensure optimal load-bearing capacity. | Regular inspections and prompt repairs maintain stability and prevent structural failures. |

| Longevity | Correct installation prevents premature deterioration and extends the lifespan of the base plates and sole boards. | Regular cleaning, maintenance, and protective measures safeguard against wear and tear. |

| Performance | Accurate installation maintains consistent performance and structural integrity. | Proactive maintenance measures sustain optimal performance over time. |

Importance of Quality Base Plate and Sole Board Selection

When it comes to construction projects, the selection of base plates and sole boards is of utmost importance. The quality of these building materials directly affects the structural support and stability of the entire construction. Therefore, it is crucial to choose base plates and sole boards that are reliable, durable, and specifically designed for the intended purpose.

Using high-quality base plates and sole boards offers numerous benefits. Firstly, they provide a strong foundation base plate, ensuring that the structure remains stable and secure. The use of substandard products can compromise the structural integrity and lead to long-term issues, potentially endangering the safety of occupants.

Furthermore, quality base plates and sole boards are essential for providing structural support. They distribute the weight and loads efficiently, preventing excessive stress on the overall construction. This helps to minimize the risk of structural failure and ensures the longevity of the building.

Another advantage of selecting reliable base plates and sole boards is their resistance to environmental factors. High-quality materials are often engineered to withstand various weather conditions, including moisture, temperature changes, and insect damage. This enhances the durability and performance of the construction, reducing the need for frequent repairs and maintenance.

On the other hand, using substandard or compromised base plates and sole boards can have serious consequences. These products may lack the necessary strength and stability, leading to structural deficiencies and potential safety hazards. Additionally, they may degrade rapidly over time, resulting in costly repairs or even the need for complete reconstruction.

Sourcing Quality Construction Supplies

When sourcing base plates and sole boards, it is essential to partner with reliable suppliers who offer high-quality construction materials. Conduct thorough research and choose suppliers who have a proven track record in delivering durable, dependable products.

Before making a purchase, thoroughly evaluate the specifications and certifications of the base plates and sole boards. Look for reputable brands that adhere to industry standards and conduct quality control measures to ensure consistent excellence.

Consider consulting with experienced engineers or construction professionals who can provide guidance on selecting the most suitable base plates and sole boards for your specific project requirements. Their expertise will help ensure that you make informed decisions and invest in building materials that meet the highest standards.

By prioritizing the selection of quality base plates and sole boards, you are making a sound investment in the long-term integrity and stability of your construction projects. Remember, the strength of a building lies in its foundation, and choosing reliable construction supplies is a crucial step towards ensuring a safe and durable structure.

Conclusion

In conclusion, base plates and sole boards play a crucial role in the construction industry, providing the necessary structural support and foundation for buildings and various structures. These building materials, such as construction base plates, wooden sole boards, and engineered sole boards, are essential components that contribute to the overall strength, stability, and durability of constructions.

Throughout this article, we have explored the importance of base plates and sole boards, delving into their functions, types, installation, and maintenance. We have highlighted the key differences between these components and their respective applications in different construction scenarios.

It is vital to select high-quality base plates and sole boards to ensure the long-term integrity of a construction project. By following the proper installation and maintenance procedures, construction professionals can enhance the performance and lifespan of these critical building supplies.

From foundation base plates to engineered sole boards, it is evident that base plates and sole boards are indispensable elements in the construction industry. Their significance cannot be overstated, as they contribute not only to the structural stability of buildings but also to the safety and overall success of construction projects.

FAQ

What is the purpose of a base plate in construction?

A base plate is a vital component in construction that serves as a foundation for various structures. It provides a solid and stable surface for structural support, distributing the weight evenly and preventing settling or shifting.

What materials are typically used for base plates?

Base plates are commonly made from steel or concrete, as these materials offer excellent strength and durability. Steel base plates are often used in steel frame constructions, while concrete base plates are suitable for both concrete and steel structures.

What types of base plates are available in the market?

There are several types of base plates available, including square, rectangular, and circular designs. The choice of base plate depends on the specific construction requirements and the load-bearing capacity needed for the structure.

How important is proper installation of base plates?

Proper installation of base plates is crucial for ensuring the stability and longevity of the overall structure. The base plates need to be accurately positioned and securely anchored to the foundation, following industry guidelines and best practices.

What is the role of a sole board in construction?

Sole boards, also known as mudsills, provide structural support and act as a connection between the foundation and the superstructure. They distribute loads evenly, help dampen vibrations, and protect the structure from moisture and pests.

What are the different types of sole boards available?

Sole boards can be made of wood or engineered materials. Wooden sole boards are often constructed from pressure-treated lumber, while engineered sole boards are made from composite materials, offering added strength, durability, and resistance to decay and insects.

How do base plates and sole boards differ?

While both base plates and sole boards provide structural support, they have distinct characteristics and applications. Base plates are primarily used to spread and support the load of a structure, while sole boards serve as a connection between the foundation and the superstructure, providing additional stability and protection.

What are the key considerations for installing and maintaining base plates and sole boards?

Proper installation of base plates and sole boards requires following manufacturer instructions, ensuring accurate placement, and using appropriate fasteners. Regular maintenance includes inspecting for damage or deterioration, addressing any issues promptly, and keeping them free from debris and moisture.

Why is it crucial to select high-quality base plates and sole boards?

Choosing high-quality base plates and sole boards is essential for ensuring the integrity and safety of a construction project. Reliable materials offer better load-bearing capacity, resistance to environmental factors, and can prevent potential structural failures or damage.