Phone:

(+65)8319-0742

Baker scaffolds are essential construction equipment for performing overhead work tasks that require elevated access. They provide a safe and efficient solution, particularly when working at the interior of buildings or dealing with bigger materials.

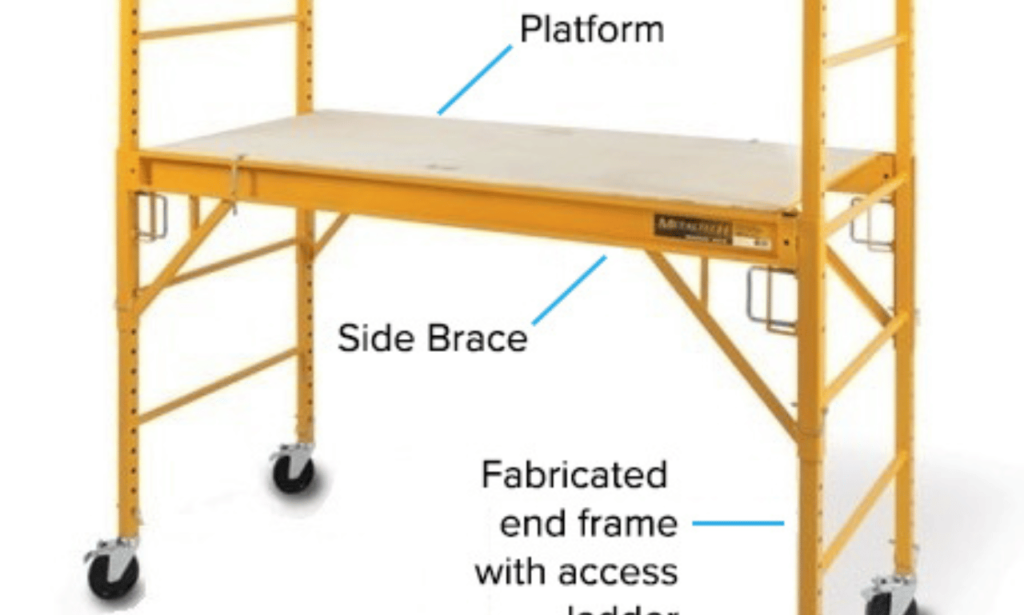

A baker scaffold, also known as a mobile or rolling scaffold, is a prefabricated scaffold platform supported by metal braces and frames with wheels. It offers easy mobility, allowing workers to move around effortlessly while maintaining stability and security.

This type of industrial scaffolding is adjustable, making it suitable for various applications in the construction industry. From accessing high ceilings and painting large areas to handling heavy materials, baker scaffolds provide the versatility needed to complete different tasks effectively.

If used correctly, a baker scaffold can greatly enhance worker safety and prevent accidents. It is crucial to understand the components, proper assembly techniques, safety standards, and potential hazards associated with this scaffolding system.

Key Takeaways:

- Baker scaffolds are manually propelled mobile scaffolds used for elevated work tasks.

- They are particularly useful for accessing high ceilings, painting large areas, and handling heavy materials.

- Components of baker scaffolds include a wood work platform, metal braces and frames, wheels, outriggers, and guardrails.

- Proper assembly and utilization of a baker scaffold is crucial for worker safety.

- Safety standards set by OSHA and ANSI should be followed when working with baker scaffolds.

Applications of Baker Scaffolds

Baker scaffolds are essential tools on construction sites for various applications, offering versatility and convenience. They are particularly useful for tasks such as accessing high ceilings, painting large areas, and handling large materials. Let’s explore these applications in more detail:

Construction Site Tasks

Baker scaffolds are commonly used in construction sites for a wide range of tasks. Their mobility and compact size make them ideal for maneuvering in tight spaces, allowing workers to navigate through different areas of a construction site with ease.

Accessing High Ceilings

When working on projects that require access to high ceilings, such as installing lighting fixtures or performing maintenance tasks, baker scaffolds provide a safe and stable platform. They offer height-adjustable work platforms that can be easily positioned at the desired level, allowing workers to work comfortably and efficiently at elevated heights.

Painting Large Areas

Painting large areas, such as walls or ceilings, can be challenging without the proper equipment. Baker scaffolds provide a stable platform for painters to work from, making it easier to cover large surfaces with precision. The adjustable height feature ensures that painters can comfortably reach different areas without straining or compromising on the quality of their work.

Handling Large Materials

On construction sites, there is often a need to handle bulky and heavy materials, such as drywall or construction panels. Baker scaffolds offer a sturdy platform for workers to safely position and maneuver these materials without the risk of injury or accidents. The strong and stable framework of the scaffold supports the weight of large materials, providing a secure working environment.

By utilizing baker scaffolds for these applications, construction workers can enhance their productivity, improve safety, and achieve better results in their projects.

| Applications | Benefits |

|---|---|

| Accessing High Ceilings | Safe and stable platform at elevated heights |

| Painting Large Areas | Efficient coverage of large surfaces |

| Handling Large Materials | Safe and secure handling of heavy materials |

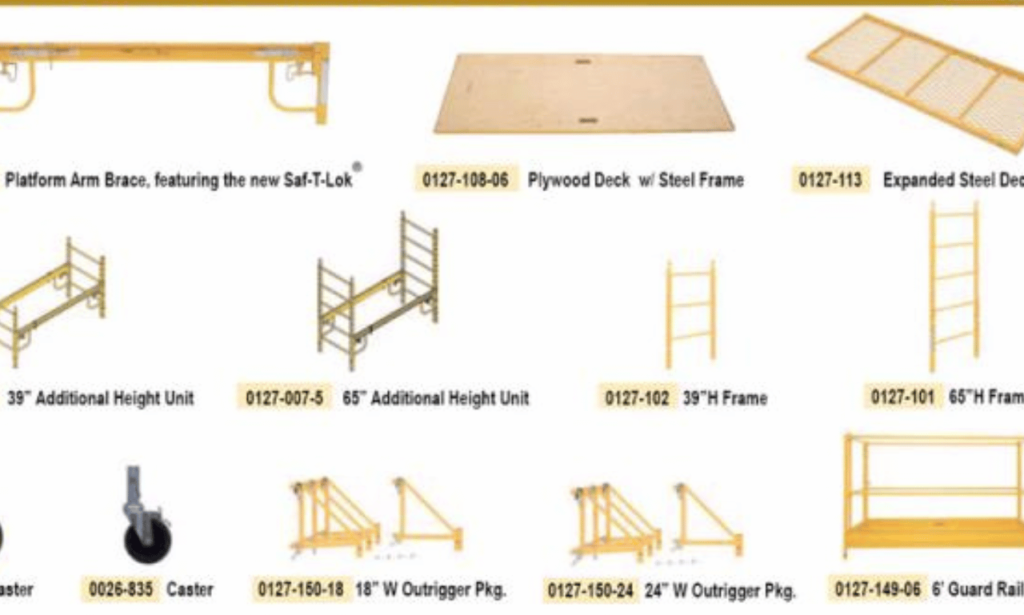

Components of Baker Scaffolds

A basic baker scaffold consists of various components that work together to provide a safe and sturdy elevated work platform. These components include:

Wood Work Platform

The wood work platform is the main surface where workers stand or place their tools and materials. It provides a stable and secure area for performing tasks.

Metal Braces

Metal braces are attached to both sides of the wood work platform to provide additional support and stability. They help distribute the weight evenly and prevent the platform from sagging or tilting.

Metal Frames

Metal frames serve as the main structure of the baker scaffold. They hold the wood work platform and provide stability and strength to the entire scaffold. Metal frames are typically adjustable in height and can accommodate different working heights.

Wheels

Wheels are attached to the base of the metal frames, allowing for easy mobility of the scaffold. They enable workers to move the scaffold to different locations without dismantling and reassembling it.

Outriggers

Outriggers are optional components that can be added to increase the stability and weight-bearing capacity of the scaffold. They extend horizontally from the base of the scaffold, providing additional support and balance, especially when working at elevated heights or on uneven surfaces.

Guardrails

Guardrails are essential safety features that help prevent falls and provide protection for workers on the scaffold. They are typically installed around the perimeter of the wood work platform, creating a barrier that prevents accidental slips or falls.

| Component | Description |

|---|---|

| Wood Work Platform | The main surface where workers stand or place their tools and materials. |

| Metal Braces | Attached to both sides of the work platform to provide additional support and stability. |

| Metal Frames | Serve as the main structure of the scaffold, holding the work platform and providing stability. |

| Wheels | Attached to the base of the metal frames for easy mobility of the scaffold. |

| Outriggers | Optional components that increase the stability and weight-bearing capacity of the scaffold. |

| Guardrails | Safety features that prevent falls and provide protection for workers on the scaffold. |

These components work together to create a sturdy and reliable baker scaffold that enables workers to perform their tasks efficiently and safely.

Proper Assembly of Baker Scaffolds

Proper assembly of a baker scaffold is essential to ensure the safety and stability of the structure. Follow these steps to correctly assemble a baker scaffold:

- Start by installing the wheels to the end frames. These wheels will allow for easy mobility of the scaffold. Secure the wheels in place using pins.

- Next, attach the side braces to the desired height on each end frame. The side braces will provide additional support and stability to the scaffold. Secure the side braces with locking pins.

- Place the wood work platform on the side rails of the scaffold. Ensure that the platform is positioned securely and evenly. Use latching pins to secure the platform in place.

- If you are using a second level of scaffolding, install additional end frames. These frames will provide the necessary support for the second level. Secure the additional end frames with swivel lock pins.

- To enhance the stability of the scaffold, install outriggers. These outriggers will help prevent tipping or tilting of the scaffold. Install the outriggers according to the manufacturer’s instructions.

- Finally, install guardrails for fall protection when working at elevated heights. Guardrails are essential safety features that help prevent accidents and protect workers.

By following these steps and utilizing the proper assembly techniques, you can ensure the proper setup and stability of your baker scaffold, creating a safe working environment for construction tasks.

| Assembly Steps | Components |

|---|---|

| Step 1 | Installing wheels |

| Step 2 | Attaching side braces |

| Step 3 | Placing work platform |

| Step 4 | Adding additional end frames |

| Step 5 | Installing outriggers |

| Step 6 | Installing guardrails |

Proper Assembly Tips

Here are some additional tips to ensure the proper assembly of your baker scaffold:

- Refer to the manufacturer’s instructions for specific assembly guidelines.

- Inspect all components for any damages or defects before assembly.

- Ensure that the scaffold is set up on a stable and level surface.

- Use a plumb and level to check the alignment of the scaffold components.

- Regularly inspect the scaffold for any signs of wear or instability.

By following these tips and guidelines, you can assemble your baker scaffold correctly and provide a safe working environment for construction tasks.

Safety Standards for Baker Scaffolds

When working with baker scaffolds, it is vital to adhere to safety standards set by OSHA and ANSI. These standards ensure that workers are protected and accidents are prevented. Familiarizing yourself with these safety standards and implementing them on construction sites is essential for a safe working environment.

OSHA Standards

The Occupational Safety and Health Administration (OSHA) establishes safety regulations and guidelines for various industries, including construction. When it comes to baker scaffolds, OSHA requires workers to receive basic training in identifying common jobsite hazards. Additionally, workers must undergo specific training for using the type of scaffold in question.

OSHA also emphasizes the importance of competent person supervision during the assembly and utilization of baker scaffolds. A competent person is an individual who has the necessary knowledge and experience to identify hazards and take appropriate measures to ensure worker safety.

ANSI Standards

The American National Standards Institute (ANSI) is another organization that sets safety standards for baker scaffolds. ANSI standards focus on providing comprehensive guidelines for the design, manufacture, and proper usage of scaffolding systems.

When utilizing baker scaffolds, it is crucial to adhere to ANSI standards to ensure that the equipment meets necessary structural requirements. This includes the use of safety features such as guardrails to prevent falls from elevated heights.

Worker Training

Proper training for workers is a crucial aspect of maintaining safety when working with baker scaffolds. In addition to the basic training required by OSHA, workers should undergo comprehensive training specific to the type of scaffold being used.

Training programs should cover topics such as scaffold assembly, inspection, and safe working practices. It is important that workers are educated on the potential hazards associated with scaffolding and are equipped with the knowledge and skills to mitigate those risks.

Competent Person Supervision

Supervision by a qualified and competent person is essential during the assembly, utilization, and dismantling of baker scaffolds. This person should possess the necessary expertise to assess potential hazards, ensure proper setup, and monitor the scaffold’s stability throughout the duration of the project.

The competent person should be responsible for conducting regular inspections to identify any issues or defects that may compromise worker safety. They should also have the authority to take corrective actions and make necessary adjustments to maintain a safe working environment.

Overall, adherence to safety standards, proper worker training, and competent person supervision are crucial for the safe use of baker scaffolds. By following these guidelines, construction companies can ensure worker safety and prevent accidents or injuries.

| Key Safety Standards | Key Points |

|---|---|

| OSHA Standards | – Basic training for workers – Specific training for scaffold type – Competent person supervision |

| ANSI Standards | – Compliance with design and usage guidelines – Structural requirements – Safety features implementation |

| Worker Training | – Comprehensive scaffold training – Hazard identification – Safe working practices |

| Competent Person Supervision | – Expertise in scaffold assembly and inspection – Ensuring proper setup and stability – Regular inspections and corrective actions |

Safety Hazards of Baker Scaffolds

Proper setup and utilization of baker scaffolds are essential for ensuring worker safety. Failure to follow safety guidelines can result in accidents and injuries. Below are some of the safety hazards associated with baker scaffolds:

- Falls from an elevated level: Working on elevated platforms without fall protection measures in place can lead to falls, resulting in serious injuries or even fatalities.

- Scaffolds tipping over: Improperly secured or unbalanced scaffolds can tip over, causing workers to fall and suffer injuries.

- Scaffold failures or collapses: Weak or damaged scaffolding components can lead to scaffold failures or collapses, endangering the workers on the platform.

- Worker injuries: Inadequate training, failure to use personal protective equipment, and lack of supervision in scaffold usage can lead to various injuries such as fractures, sprains, and head trauma.

To mitigate these safety hazards, it is crucial to prioritize the following measures:

- Provide comprehensive training to workers on proper scaffold setup and usage.

- Adhere to safety standards and regulations, such as those set by OSHA and ANSI, to ensure compliance.

- Implement appropriate fall protection measures, such as guardrails or personal fall arrest systems, to prevent falls from elevated platforms.

- Regularly inspect and maintain scaffolds to identify any defects or weaknesses that may compromise safety.

- Use stability features, including outriggers and proper weight distribution, to prevent scaffold tipping.

By addressing these safety hazards and implementing proactive safety measures, construction companies can create a safer working environment for individuals utilizing baker scaffolds.

Alternatives to Baker Scaffolds

While baker scaffolds are a popular choice for certain construction tasks, there are alternative options available. These alternatives provide different features and benefits, allowing professionals to choose the right scaffolding solution for their specific needs and projects. Some of the popular alternatives to baker scaffolds include:

Trestle Scaffolding

Trestle scaffolding is commonly used for home improvement projects and other tasks that require a stable and elevated work platform. This type of scaffolding consists of scaffold planks supported by A-frame legs. Trestle scaffolding offers a sturdy and reliable structure, making it suitable for various construction and maintenance projects.

Rolling Scaffolds

Rolling scaffolds, also known as mobile scaffolds, are designed for professionals who require greater mobility and versatility. These scaffolds feature one or more scaffold stages and locking casters, allowing them to be easily moved around a construction site. Rolling scaffolds are ideal for tasks that require frequent repositioning, such as painting, installing drywall, or working on electrical systems.

Portable Scaffolds

Portable scaffolds offer a convenient and flexible solution for professionals working on construction sites. These scaffolds are compact and lightweight, making them easy to transport and set up. Portable scaffolds are designed to provide a stable work platform for tasks that require elevation, without the need for a larger, permanent scaffolding structure. They are especially useful for small-scale projects or when working in tight spaces.

When choosing an alternative to baker scaffolds, it is important to consider factors such as the nature of the project, required mobility, stability, and ease of setup. Each type of scaffold has its own advantages and limitations, so it’s essential to assess the specific needs of the job and select the scaffolding solution that best suits the task at hand.

| Scaffold Type | Features | Benefits |

|---|---|---|

| Trestle Scaffolding | – Scaffold planks supported by A-frame legs – Stable and reliable structure | – Suitable for home improvement projects – Provides a sturdy elevated work platform |

| Rolling Scaffolds | – One or more scaffold stages – Locking casters for mobility | – Easy movement and repositioning – Ideal for tasks requiring frequent mobility |

| Portable Scaffolds | – Compact and lightweight design – Easy transport and setup | – Convenient for small-scale projects – Suitable for tight spaces |

Customer Feedback on Baker Scaffolds

Customers have provided valuable feedback on various brands of baker scaffolds, including the Pro Series scaffold, Metal-Tech scaffold, and Fortress scaffold. This feedback provides insights into the reliability and suitability of these scaffolds for different customer needs and preferences. Factors such as price, quality, and ease of use have influenced customer satisfaction and influenced their decision-making process when choosing a baker scaffold.

Pro Series Scaffold

The Pro Series scaffold has received positive feedback from customers who appreciate its durability and stability. Customers have praised its sturdy construction, which allows for safe and secure use even in demanding work environments. The Pro Series scaffold is recognized for its long-lasting performance and excellent value for money.

Metal-Tech Scaffold

Customers have expressed satisfaction with the Metal-Tech scaffold due to its versatility and ease of use. The scaffold’s adjustable features and compatibility with various accessories offer flexibility in different construction scenarios. Users appreciate the Metal-Tech scaffold’s ability to adapt to different heights and accommodate specific work requirements.

Fortress Scaffold

Feedback on the Fortress scaffold highlights its excellent build quality and reliability. Customers have found the Fortress scaffold to be sturdy and well-designed, providing a secure platform for elevated work. The scaffold’s robust construction and safety features have garnered positive reviews, making it a popular choice among construction professionals.

It is important for individuals to carefully consider their specific requirements and preferences when choosing a baker scaffold. Customer feedback serves as a valuable resource in making an informed decision, taking into account factors such as brand reputation, customer satisfaction, and the intended use of the scaffold.

| Baker Scaffold Brand | Customer Feedback |

|---|---|

| Pro Series Scaffold | Durable and stable construction, excellent value for money |

| Metal-Tech Scaffold | Versatile and easy to use, adjustable features for different work scenarios |

| Fortress Scaffold | Robust build quality, secure platform for elevated work |

Safety Tips for Working with Baker Scaffolds

When it comes to working with baker scaffolds, safety should always be a top priority. These tips will help you ensure a secure and accident-free work environment:

- Use outriggers: Outriggers are essential for increasing stability and preventing the scaffold from tipping over. Make sure to install them properly according to the manufacturer’s guidelines.

- Secure wheels: Accidental falls can occur if the wheels are not securely attached. Double-check that the wheels are locked in place before using the scaffold.

- Proper setup on a stable surface: The scaffold should be set up on a firm and stable surface, such as concrete or solid ground. Avoid uneven or soft terrain that can compromise stability.

- Plumb and level platforms: Ensure that the scaffold platforms are plumb (vertical) and level (horizontal). This will provide a stable working surface and minimize the risk of falls.

- Safe access to platforms: Use sturdy staircases or properly secured ladders to access the scaffold platforms. Avoid climbing on the guardrails or attempting to reach the platforms from unstable surfaces.

Remember, it is crucial to adhere to safety guidelines and regularly inspect the scaffold for any damages or defects. By following these safety tips, you can significantly reduce the risk of accidents and injuries while working with baker scaffolds.

| Safety Tip | Description |

|---|---|

| Use outriggers | Installing outriggers can enhance the stability of the scaffold and prevent tipping over. |

| Secure wheels | Ensure that the wheels are securely attached to the scaffold to prevent accidental falls. |

| Proper setup on a stable surface | Set up the scaffold on a firm and stable surface, such as concrete or solid ground, to maintain stability. |

| Plumb and level platforms | Verify that the scaffold platforms are vertically plumb and horizontally level for a stable working surface. |

| Safe access to platforms | Use secure staircases or ladders to access the scaffold platforms, avoiding unstable or unsafe methods. |

Where to Buy Baker Scaffolds

If you’re looking to purchase baker scaffolds for your construction projects, Lowe’s offers a convenient solution. With a wide selection of options and accessories available, Lowe’s is a reliable retailer for all your scaffolding needs.

Whether you prefer the convenience of online shopping or want to see the products in person, Lowe’s caters to your preferences. Their website allows you to make an online purchase and have the scaffolds delivered to your doorstep. Alternatively, you can choose the in-store pickup option for immediate availability.

When deciding where to buy your baker scaffolds, it’s important to consider factors such as the brand, material, and customer reviews. Lowe’s provides a range of reputable brands and various materials to meet different project requirements. By reading customer reviews, you can gain insights into the quality and performance of the scaffolds, helping you make an informed purchasing decision.

Choosing the right retailer is crucial to ensure you get high-quality scaffolds that meet your specific needs. With Lowe’s, you can trust their expertise and experience in providing reliable construction equipment. Whether you’re a professional builder or a DIY enthusiast, Lowe’s has you covered when it comes to baker scaffolds.

Importance of Proper Utilization of Baker Scaffolds

Proper utilization of baker scaffolds is crucial for ensuring worker safety, preventing accidents, and complying with industry regulations. By following safety guidelines, providing adequate training, and implementing regular inspections and maintenance, construction companies can create a safe and efficient working environment.

Worker safety should be the top priority when using baker scaffolds. These elevated platforms carry inherent risks, and it is essential to implement preventive measures to minimize accidents and injuries. Adhering to safety regulations not only protects workers but also helps organizations avoid costly legal consequences and reputational damage.

Worker Safety

Worker safety is paramount in any construction project. Proper utilization of baker scaffolds reduces the risk of falls, collapses, and other accidents, creating a secure environment for workers to perform their tasks. This includes:

- Ensuring the scaffold is correctly assembled, stable, and properly secured

- Using appropriate safety equipment, such as harnesses and guardrails

- Implementing fall protection measures, like safety nets or personal fall arrest systems

- Training workers on scaffold usage, hazard recognition, and emergency procedures

By prioritizing worker safety, construction companies demonstrate their commitment to the well-being of their employees and establish a positive safety culture on the job site.

Accident Prevention

Proper utilization of baker scaffolds significantly reduces the likelihood of accidents and associated injuries. Common accidents when working with scaffolds include falls from heights, scaffold collapses, and being struck by falling objects. Adhering to safety guidelines and utilizing scaffolding correctly helps prevent these incidents.

Regular inspections to identify and address any potential hazards or structural issues are crucial. Additionally, training workers to recognize and report unsafe conditions contributes to accident prevention. Construction companies should promote a proactive approach to safety, encouraging employees to actively participate in hazard identification and risk mitigation efforts.

Compliance with Regulations

Proper utilization of baker scaffolds ensures compliance with industry regulations, such as those set by OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). These regulations outline specific requirements for scaffolding design, assembly, and usage, aiming to protect workers from harm.

Construction companies must stay informed about the latest safety standards and incorporate them into their operations. Compliance not only guarantees the well-being of workers but also helps build credibility and trust within the industry.

Regular training sessions, safety audits, and internal monitoring systems can help organizations maintain compliance with regulations and swiftly address any identified areas of improvement.

| Benefits of Proper Utilization of Baker Scaffolds | Worker Safety | Accident Prevention | Regulatory Compliance |

|---|---|---|---|

| Reduces the risk of falls, collapses, and accidents | Creates a secure work environment | Prevents injuries and associated costs | Ensures adherence to safety regulations |

| Establishes a positive safety culture on the job site | Protects the well-being of employees | Mitigates reputational damage | Builds credibility and trust within the industry |

| Avoids costly legal consequences |

By recognizing the importance of proper utilization of baker scaffolds, construction companies can protect their workers, prevent accidents, and ensure compliance with regulations. Prioritizing worker safety and implementing proactive measures ultimately leads to successful construction projects with minimized risks and increased productivity.

Conclusion

In conclusion, using a baker scaffold in construction work offers several benefits. The first and foremost is enhanced safety. By adhering to proper assembly techniques and safety standards, workers can minimize the risk of accidents and injuries. The mobility provided by the scaffold’s rolling feature allows for easy movement around the construction site, increasing efficiency and productivity.

Another advantage of using a baker scaffold is its versatility. This type of scaffold can be utilized for various tasks, such as accessing high ceilings, painting large areas, and handling bulky materials. Its adjustable height feature enables workers to customize the working platform to suit their specific needs, making it a flexible choice for different construction projects.

However, it is important to consider safety considerations when using a baker scaffold. Workers should receive proper training and follow industry guidelines to prevent hazards such as falls, scaffold tipping, or failures. Adhering to safety regulations and prioritizing worker safety are critical for the success of any construction project.

FAQ

What are the applications of baker scaffolds?

Baker scaffolds are commonly used for accessing higher ceilings, painting larger areas, and handling larger materials on construction sites.

What components make up a baker scaffold?

A baker scaffold consists of a wood work platform, metal braces, metal frames, wheels, optional outriggers for stability, and optional guardrails for fall protection.

How do I assemble a baker scaffold?

To assemble a baker scaffold, start by installing the wheels and securing them with pins. Attach the side braces at the desired height and secure them with locking pins. Place the work platform on the side rails and secure it with latching pins. Additional components like end frames, outriggers, and guardrails can be added as needed.

What safety standards should be followed when using baker scaffolds?

Baker scaffolds are subject to safety standards set by OSHA and ANSI. Workers should have basic training in recognizing common jobsite hazards and additional training for the specific type of scaffold being used. Scaffolds should be assembled and utilized under the supervision of a qualified and competent person, and fall protection measures should be provided for workers at elevated heights.

What are the safety hazards associated with baker scaffolds?

Safety hazards of baker scaffolds include falls from an elevated level, scaffolds tipping over, and scaffold failures or collapses. Proper setup, adherence to safety guidelines, and the use of appropriate fall protection measures and stability features can help prevent accidents and minimize the risk of worker injuries.

Are there alternatives to baker scaffolds?

Yes, alternatives to baker scaffolds include trestle scaffolding, which uses scaffold planks supported by A-frame legs, and rolling or portable scaffolds designed with locking casters for greater mobility.

What are some customer-favored brands of baker scaffolds?

Some popular brands of baker scaffolds include Pro Series, Metal-Tech, and Fortress. Customer satisfaction varies based on factors such as price, quality, and ease of use.

What safety tips should I follow when working with baker scaffolds?

When working with baker scaffolds, it is important to use outriggers for increased stability, securely attach wheels to prevent accidental falls, set up the scaffold on a firm and stable surface, ensure platforms are plumb and level, and provide safe access to platforms. Regular inspections and adherence to safety guidelines are also crucial.

Where can I buy baker scaffolds?

Baker scaffolds can be purchased from retailers such as Lowe’s, both online and for in-store pickup. It is important to consider factors such as brand, material, and customer reviews when making a purchasing decision.

Why is proper utilization of baker scaffolds important?

Proper utilization of baker scaffolds is essential for worker safety, accident prevention, and compliance with industry regulations. By following safety guidelines, providing adequate training to workers, and regularly inspecting and maintaining the scaffold, construction companies can create a safe and efficient working environment.

Are baker scaffolds versatile in construction work?

Baker scaffolds offer enhanced safety, easy mobility, and versatility in construction work. They can be used for accessing high ceilings, painting large areas, and handling larger materials, making them a valuable tool in construction projects.