Phone:

(+65)8319-0742

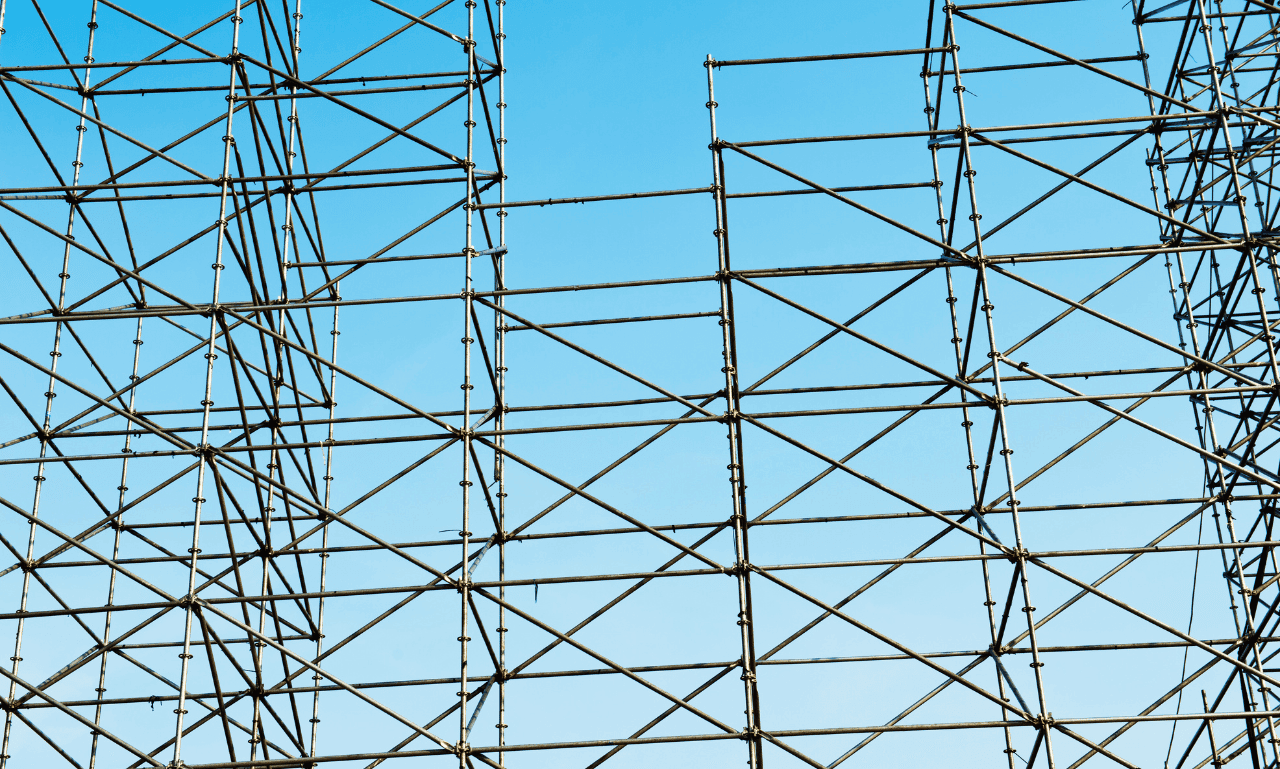

The tangible evolution of construction solutions is exemplified by multidirectional scaffolding, a culmination of versatility and robust engineering. This innovative scaffold design has set benchmarks in adaptability, propelling efficiency across various construction scenarios. Pilosio’s MP multidirectional system highlights such advancements, integrating ease of assembly with the capacity to tackle the nuanced demands of complex projects.

Versatile scaffolding solutions, such as these, not only provide an infrastructure for workers but also serve as a testament to the industrial strides in construction methodologies. Multidirectional scaffolding represents a quantum leap from conventional systems, balancing the rigidity required for high-load bearing with the malleability to conform to diverse structural shapes.

Key Takeaways

- Embrace the cutting-edge in versatile scaffolding solutions with multidirectional systems.

- Discover the simplicity and strength of the MP multidirectional scaffolding system.

- Innovative scaffold design meets the multifaceted needs of modern construction.

- Optimize work with scaffolding that offers versatility in assembly and application.

- Ensure project success with construction solutions adaptable to complex scenarios.

An Overview of Multidirectional Scaffolding Technology

The realm of construction has seen a revolutionary shift with the advent of multidirectional scaffolding, which has emerged as a beacon of innovative scaffold design. This powerful equipment has redefined the possibilities for builders and architects, transforming how structures are supported during the construction phase.

The Evolution of Scaffolding Design

Gone are the days of static and unyielding scaffold structures. The drive towards better, more efficient construction equipment has poised multidirectional scaffolding at the forefront of industry innovations. The newer systems facilitate quick adjustments while maintaining rigorous safety standards, a hallmark of safe scaffolding solutions.

Characteristics of Multidirectional Scaffolding

Integral to the innovative scaffold design is a complex of features that distinguishes it from its forerunners. The 8-connection rosette is noteworthy for its versatility and ease of component attachment, producing a durable scaffolding system that stands resilient against both time and environmental wear.

Enhanced Load-Bearing Capacity and Adaptability

This technology is not only merited for its strength but also for its extensive adaptability, allowing structures to rise in forms that were once thought unachievable. Its rigorous load-bearing capacity dovetails with the needs of modern construction, presenting a truly safe scaffolding solution. Brands such as GBM, Pilosio, and Altrad exemplify a synergy between compatibility and performance, ensuring that practices with multidirectional scaffolding are both secure and groundbreaking.

| Feature | Benefit |

|---|---|

| Rapid Lock System | Decreases assembly and disassembly time |

| 8-connection Rosette | Enhances structural configuration possibilities |

| Interoperability | Seamless integration with various brands and systems |

| Galvanized Steel | Provides long-term durability and corrosion resistance |

| Certification Compliance | Ensures adherence to EN 17067:2013, supporting safe sclaffolding solutions |

Key Components of a Multidirectional Scaffolding System

The efficacy of a versatile scaffolding system is contingent on the robustness and ingenuity of its components. Assessing the multidirectional scaffolding components represents a vital step in comprehending this system’s functional capacity and operational scope. Scaffolding systems are composed of numerous pivotal parts that work in synergy, allowing for higher efficiency and increased adaptability in constructing temporary structures and platforms.

Renowned for a reputation of using quality scaffolding materials, the GBM brand exemplifies this excellence through its robust and dependable items that form the backbone of a versatile scaffolding system. These materials are engineered to withstand the rigors of varied construction environments, ensuring durability and safety. Incorporating an innovative scaffold design, the GBM multidirectional scaffolding system facilitates the swift assembly and flexible configuration of scaffold structures.

- Standards (Verticals) – the vertical pipes that support the weight of the system.

- Ledgers – horizontal components that connect standards and create the scaffolding framework.

- Base Collars – foundation pieces that stabilize the standards upon the ground.

- Diagonal Braces – these criss-cross between standards providing lateral support to the structure.

- Brackets and Wall Ties – accessories that enhance the overall stability when anchored to solid surfaces.

Identifying each component by size and weight ensures a more streamlined process for construction professionals. This also creates an intuitive system that can be readily assembled and disassembled, boosting job-site productivity.

| Component Type | Description | Function |

|---|---|---|

| Standards | Vertical posts made with galvanized steel | Provide the vertical framework and bear loads |

| Ledgers | Horizontal components connecting the standards | Form the transversal support for decks and platforms |

| Base Collars | Foundation elements that secure the standards to the ground | Stabilize the base of the scaffolding structure |

| Diagonal Braces | Angled components that connect standards at various levels | Prevent the swaying or collapse of the scaffold |

| Wall Ties | Accessories used for tying the scaffold to a solid surface | Augment structural integrity by securing the scaffold to a building or structure |

In essence, these elements, meticulously produced from galvanized steel, not only guarantee resilience but also contribute to the longevity of the versatile scaffold system. It is through the judicious application of these high-caliber elements that a multidirectional scaffolding system can potentially revolutionize construction efficiencies.

Scaffolding Efficiency: The Impact of Innovative Scaffold Design

The advent of innovative scaffold design has ushered in a new era for construction sites, emphasizing not just the speed of completion but the pivotal role of efficient construction equipment. Such progressive design is a clear response to the increasing demand for swift yet safe assembly and the longevity of constructs in the field.

Assembly and Disassembly: Time-Saving Features

The integration of quick-lock systems in modern scaffolding is a testament to the industry’s commitment to efficiency. The wedge-head and rosette system facilitates rapid attachment and stabilization without the traditional reliance on screws, considerably reducing the time needed for erecting and dismantling durable scaffolding.

Durability Considerations: Quality Scaffolding Materials

The application of a hot-dip galvanized finish is more than a mere aesthetic choice; it’s an investment in resilience. This enduring treatment protects the metal against the harshness of the elements, significantly prolonging the service life of scaffolds and maintaining the integrity of durable scaffolding throughout numerous projects.

Safety Measures in Scaffolding

Equally important to the conversation is safety, where safe scaffolding solutions play a vital role in the welfare of construction personnel. Through a combination of stringent manufacturing standards and meticulous design, modern scaffolds provide stable platforms and robust safety features to ensure a secure workspace high above the ground.

In conclusion, the synergistic effect of these elementsâtime-saving features, material durability, and uncompromised safetyâcreates a sophisticated framework that firmly establishes the relevance and necessity of such efficient construction equipment in today’s ambitious construction landscape.

Multidirectional Scaffolding Applications in Various Industries

The versatility and adaptability of multidirectional scaffolding shine across an array of industrial applications, each with its distinct set of requirements and challenges. Notably, industries such as shipbuilding and the Oil & Gas sector have leveraged reliable scaffolding platforms for their ability to mold into custom configurations like circular scaffolding and suspended structures, addressing their unique project demands efficiently.

Markedly, the entertainment industry has taken advantage of the versatile scaffolding system to create mobile towers and stages for events, further emphasizing the systemâs capacity for adaptation and ease of mobility. The aero-naval sector also reflects the integral role of high-performance scaffold structures in maintenance and renovation tasks. Below is an exploration of specific industrial applications where multidirectional scaffolding has been particularly transformative.

| Industry | Application | Benefits of Multidirectional Scaffolding |

|---|---|---|

| Shipbuilding | Manufacture and repair of vessels | Custom configurations for large structures, circular and dynamic shapes |

| Oil & Gas | Offshore platforms | Suspended scaffold for hard-to-reach areas, weather-resistant structures |

| Entertainment | Stages for concerts and events | Mobile towers for easy assembly and disassembly, ensuring rapid venue changes |

| Aero-Naval | Airplane and ship maintenance | High-performance scaffolds for complex maintenance, ensuring worker safety |

Such diverse utility undeniably positions multidirectional scaffolding as a cornerstone in contemporary construction and maintenanceâa testament to its status as a reliable scaffolding platform suited for intricate and demanding industry projects.

The Compatibility and Integration of Scaffolding Systems

The realm of contemporary construction has always demanded innovative solutions that not only promise efficiency and safety but also flexibility. Multidirectional Scaffolding stands at the forefront of this vanguard with notable features that underpin versatile scaffolding systems. A critical facet nurturing this innovation is how these structures blend seamlessly with different brands, highlighting the intrinsic value of interoperability within the industry.

Interoperability with Other Scaffolding Brands

In essence, the sheer capability of Multidirectional Scaffolding to integrate and work alongside various established scaffolding brands eradicates the boundaries previously demarcated by brand-exclusive designs. The application of customizable solutions facilitates the assembly of multifaceted structures, encouraging a collaborative platform across brands without the burden of incompatibility.

Customizable Solutions for Complex Constructions

Constructions of complex geometries no longer intimidate the workspace; instead, they endorse the versatility of scaffolding systems. The ability to tailor these assemblies for intricate projects is a testament to the dynamic nature of reliable scaffolding platforms. From industrial plants to avant-garde architectural expressions, the potential for adaptive construction scaffolding is limitless with Multidirectional Scaffolding.

Specialized Components for Tailored Projects

When it comes to individualized components, the deliverables span from metal boards to mobile rosettes and adjustable base jacks. Each component, meticulously coded for ease of recognition and precision, contributes to a cohesive whole that, in turn, champions customizable solutions. It is the tailored nature of these projects that manifests the epitome of a reliable scaffolding platform, engineered for specificity and structural integrity alike.

Addressing Unique Construction Challenges with Multidirectional Scaffolding

Meeting the demands of innovative construction projects requires a versatile scaffolding system capable of adapting to complex geometries and environments. Multidirectional scaffolding systems not only facilitate but significantly enhance the efficiency and safety of construction operations under challenging conditions.

Design Flexibility for Irregular Structures

The dynamics of modern architecture often involve structures with curves, angles, and intricate design aspects that can pose significant construction challenges. The innovative scaffold design of multidirectional scaffolding systems, with their modular nature, provides vital design flexibility. This scaffolding allows for precision alignment and secure connections, even around the most irregular of forms, vital for projects with custom architectural features.

High-Performance Scaffold Structures in Harsh Environments

Construction sites exposed to extreme weather conditions or corrosive environments necessitate high-performance scaffold structures that can withstand such rigors. Engineered for durability and stability, the robust framework of multidirectional scaffolding performs reliably in harsh conditions, ensuring work can proceed safely and without interruption.

Reliable Scaffolding Platforms for Maintenance and Renovation

Routine maintenance and renovation tasks, especially at height or within confined spaces, demand not only flexibility but also guaranteed safety. A safe scaffolding solution, such as that provided by the tried-and-tested multidirectional systems, offers dependable platforms that cater to these precise requirements. Integrated safety features such as guardrails and the capacity for secure harness attachments ensure that workers are adequately protected while performing their duties.

- Modularity: The versatile nature of system components accommodates a plethora of structural configurations.

- Interconnectivity: Facilitates complex constructions by allowing various orientations to meet specific project needs.

- Load Capacity: Consolidated design supporting enhanced load distribution for worker security and material handling.

The following table illustrates the versatility and adaptability of a multidirectional scaffolding system in managing unique construction challenges.

| Feature | Benefit | Application |

|---|---|---|

| 8-Way Connectors | Enables multidirectional assembly | Irregular architectural structures |

| Adjustable Bases | Compensates for uneven ground | Sloped or rugged terrain |

| High-Strength Materials | Resistance against harsh conditions | Industrial and maritime environments |

| Safety Enhancements | Protective features for worker’s safety | High-rise maintenance projects |

| Customizable Platforms | Configurable for specific tasks | Restoration and renovation work |

As construction projects continue to expand in scope and complexity, the role of versatile systems like multidirectional scaffolding becomes increasingly essential. Not only do these systems ensure that construction can proceed efficiently and safely, but their design also means that they can be easily adapted to meet the evolving demands of an industry always pushing towards innovation.

Conclusion

In the realm of construction, multidirectional scaffolding stands as a transformative innovation, enabling project teams to navigate the varying complexities and demands of today’s building environments. Seamlessly merging the tried-and-true practices with ground-breaking techniques, these systems advocate for a construction process that is at once agile and robust, offering rapid assembly and steadfast durability. This harmony between historical scaffolding methods and present-day advancements has cemented multidirectional scaffolding’s position as a leading choice for contractors and builders.

As the cornerstone of safe scaffolding solutions, these scaffolding systems lay the framework for a safer workplace. Occupational risks are mitigated by features designed to ensure a stable, secure platform from which workers can operate. The inherent versatility and adaptability of high-performance scaffold structures are evident in their widespread application, from the intricate blueprints of modern architecture to the high stakes of industrial maintenance.

Looking ahead, stakeholders in the construction sector can anticipate a landscape dominated by efficient construction equipment like multidirectional scaffolding, facilitating elevated productivity levels and adhering to rigorous safety benchmarks. As these scaffolding solutions continue to evolve, they promise not only to meet but to exceed the aspirations for tailor-made, flexible, and above all, safe construction platforms. The widespread applications of multidirectional scaffolding serve as a testament that the future is here, and it is built on the back of innovative scaffold design.

FAQ

What Is Multidirectional Scaffolding?

Multidirectional scaffolding is a modern, versatile scaffolding system that offers flexibility and industrial efficiency. It’s known for its rapid assembly, modularity, and superior load-bearing capacity. This type of scaffold can adapt to various construction environments, making it suitable for a wide range of applications.

How Does Innovative Scaffold Design Contribute to Construction Efficiency?

Innovative scaffold designs, such as those incorporating multidirectional scaffolding technology, contribute to construction efficiency by streamlining assembly and disassembly processes. These designs often eliminate the need for screws and use wedge-heads and rosettes, which helps to reduce construction time and enhance safety.

What Are the Safety Advantages of Using Multidirectional Scaffolding Systems?

Safety advantages include the system’s compliance with safety certifications (e.g., EN 17067:2013), facilitation of secure work platforms, and the attachment points that allow for enhanced stability and fall protection. The design also allows for safe and intuitive assembly, reducing the risk of accidents on site.

Can Multidirectional Scaffolding Be Integrated with Other Scaffold Systems?

Yes, multidirectional scaffolding systems are designed for compatibility and can often be integrated with other scaffolding brands. This interoperability ensures they can be used in an array of construction environments and for various applications, enhancing the system’s flexibility and the ability to customize solutions.

What Types of Projects Can Benefit from Multidirectional Scaffolding?

Multidirectional scaffolding can be utilized for an array of projects, including the construction and maintenance of façades, staircases, cantilevers, mezzanines, shoring structures, high-capacity towers, stages, and grandstands. It is particularly beneficial for complex setups that require adaptable and high-performance scaffold structures.

How Does the Load-Bearing Capacity of Multidirectional Scaffolding Compare to Traditional Systems?

The load-bearing capacity of multidirectional scaffolding is often superior to traditional systems due to the innovative design and quality of materials used. The specialized rosettes and connection points facilitate greater load distribution, making these systems suitable for heavy-duty applications.

What Materials Are Used in the Construction of Multidirectional Scaffolding Components?

High-quality steel is commonly used for the construction of multidirectional scaffolding components, with surface treatments such as hot-dip galvanization to ensure durability and resistance against corrosion. This combination of material choice and treatment ensures a long-lasting, reliable construction support system.

Are Multidirectional Scaffolding Systems Suitable for Use in Harsh Environments?

Yes, due to their robust design and material choices, multidirectional scaffolding systems are suitable for use in harsh environments. They provide enhanced load-bearing capacity, stability, and safety features necessary for challenging conditions such as those found in shipbuilding and the Oil & Gas industry.