Phone:

(+65)8319-0742

Scaffold tower wheels are an essential component for ensuring smooth operation on construction sites. These wheels provide reliable mobility and secure locking mechanisms, allowing for easy movement of scaffold towers. Designed to withstand heavy loads, scaffold tower wheels offer stability and safety for workers, enabling construction projects to be completed efficiently and effectively.

Key Takeaways:

- Scaffold tower wheels are crucial for smooth movement on construction sites.

- They provide reliable mobility and secure locking mechanisms.

- Designed to withstand heavy loads, scaffold tower wheels ensure stability and safety.

- They contribute to the efficiency and effectiveness of construction projects.

- Choosing high-quality scaffold tower wheels is essential for optimal performance and longevity.

Types of Scaffold Tower Wheels

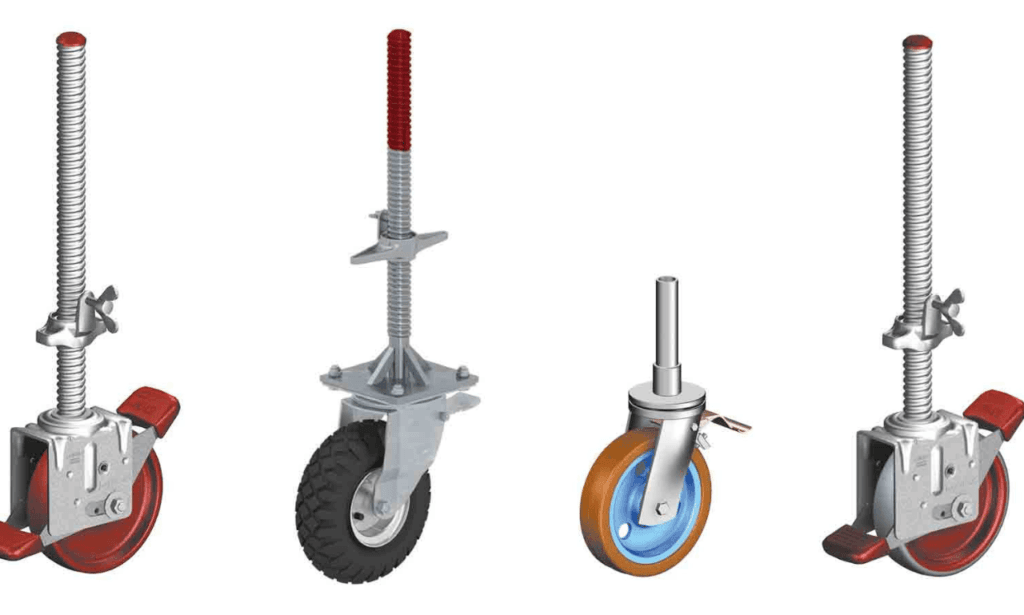

When it comes to scaffold tower wheels, there are different types available in the market to suit different construction needs. Two popular options are heavy-duty scaffold wheels and adjustable scaffold caster wheels.

Heavy-duty Scaffold Wheels

Heavy-duty scaffold wheels are specifically designed to handle heavy loads and provide stability, even on uneven surfaces. These wheels are made with durable materials and robust construction, ensuring long-lasting performance in demanding construction environments. They offer reliable support and maneuverability, making them ideal for projects that involve heavier scaffolding structures. With their superior load-bearing capacity, heavy-duty scaffold wheels can accommodate the weight of equipment and workers, ensuring a secure foundation for a safe and productive work environment.

Adjustable Scaffold Caster Wheels

Adjustable scaffold caster wheels are another popular option for scaffold towers. These wheels offer flexibility in terms of maneuverability and positioning. They can be easily adjusted to different heights and angles, allowing workers to adapt the scaffold tower to specific construction requirements. Whether it’s the need for precise alignment or navigating tight spaces, adjustable scaffold caster wheels provide the necessary mobility and versatility. This capability enables construction professionals to efficiently complete tasks while maintaining stability and safety.

Both heavy-duty scaffold wheels and adjustable scaffold caster wheels play a significant role in enhancing the functionality and effectiveness of scaffold towers. The choice between these types depends on the specific demands of the construction project, such as load capacity, terrain conditions, and maneuverability requirements. Consulting with experts or suppliers can help in selecting the most suitable scaffold tower wheels for the job at hand.

Table: Comparison of Heavy-duty Scaffold Wheels and Adjustable Scaffold Caster Wheels

| Features | Heavy-duty Scaffold Wheels | Adjustable Scaffold Caster Wheels |

|---|---|---|

| Load Capacity | Designed to support heavy loads | Can accommodate varying load demands |

| Stability | Provide stability on uneven surfaces | Offer stability and flexibility |

| Maneuverability | May require more effort to maneuver | Easily adjustable for optimal maneuverability |

| Construction Environment | Suitable for demanding construction sites | Adaptable to different construction needs |

By understanding the unique features and benefits of both heavy-duty scaffold wheels and adjustable scaffold caster wheels, construction professionals can make informed decisions when selecting the most appropriate wheels for their scaffold towers.

Features of Scaffold Wheel Locking Mechanism

Scaffold tower wheels are equipped with a robust locking mechanism that plays a crucial role in ensuring the stability and safety of construction sites. The scaffold wheel locking mechanism prevents the wheels from moving when the scaffold tower is in use, providing workers with a secure and reliable platform for their tasks.

One of the key features of scaffold tower wheels is the inclusion of scaffolding wheels with brakes. These brakes allow for easy and efficient locking and unlocking of the wheels, enabling workers to securely position the scaffold tower. By engaging the brakes, the scaffold tower remains stationary, minimizing the risk of accidental movement or instability, and maintaining a safe working environment.

The scaffold wheel locking mechanism, coupled with the inclusion of brakes, enhances the overall safety of construction projects. The locking mechanism ensures that the scaffold tower remains firmly in place during use, reducing the chances of accidents or mishaps. Workers can focus on their tasks without worrying about the scaffold tower shifting or moving unexpectedly.

Additionally, the brakes on scaffolding wheels provide an added layer of security. When the brakes are engaged, the scaffold tower remains stationary, even on uneven or slippery surfaces. This feature is particularly important when working at elevated heights, as it helps prevent potential falls or accidents due to sudden movement of the scaffold tower.

In summary, the features of the scaffold wheel locking mechanism and the inclusion of scaffolding wheels with brakes contribute significantly to the stability and safety of construction sites. These features ensure that the scaffold tower remains securely positioned, minimizing the risk of accidents and creating a secure working environment for construction workers.

Benefits of Mobile Scaffold Tower Wheels

Mobile scaffold tower wheels provide a range of benefits for construction projects. These scaffold tower rolling casters enable easy mobility of the scaffold tower, allowing workers to move the tower from one location to another without the need for disassembly. This not only saves valuable time but also reduces effort, increasing productivity on-site.

One of the key advantages of mobile scaffold tower wheels is their ability to provide convenience in accessing hard-to-reach areas. With the mobility offered by these wheels, workers can effortlessly maneuver the scaffold tower into tight spaces or areas with restricted access. This allows for greater efficiency and flexibility in completing construction tasks.

Additionally, mobile scaffold tower wheels provide the flexibility to adjust the height and position of the tower easily. This is particularly useful when working on projects that require frequent adjustments or changes in elevation. The ability to quickly and smoothly reposition the scaffold tower ensures that workers can execute their tasks effectively.

| Benefits of Mobile Scaffold Tower Wheels |

|---|

| Easy mobility of scaffold tower |

| Time and effort-saving |

| Convenience for accessing hard-to-reach areas |

| Flexibility in adjusting height and position |

Overall, the benefits of mobile scaffold tower wheels contribute significantly to the efficiency and effectiveness of construction projects. By employing these rolling casters, workers can easily transport scaffold towers without disassembly, access challenging areas, and make necessary adjustments. This enhances productivity and streamlines operations on-site, ultimately leading to successful project completion.

The Importance of High-Quality Scaffold Wheels

High-quality scaffold wheels are an essential component for construction projects, providing crucial benefits such as safety, durability, and efficiency. These wheels are specifically designed to withstand heavy loads and ensure the stability of scaffold towers. By using scaffold tower replacement wheels, construction workers can enhance site productivity while maintaining a secure working environment.

One of the key advantages of high-quality scaffold wheels is their ability to withstand heavy loads. These wheels are engineered to support the weight of the scaffold tower, ensuring that it remains stable during operation. By investing in sturdy wheels, construction companies can alleviate concerns about potential wheel failures that can pose significant risks to worker safety.

Durability is another important feature of high-quality scaffold wheels. These wheels are built to endure the rigorous demands of construction sites, reducing the need for frequent replacements. As a result, projects can proceed without the interruption and cost associated with wheel maintenance or replacement.

Additionally, high-quality scaffold wheels meet safety standards and regulations established within the industry. These wheels are manufactured using robust materials and undergo rigorous testing to ensure their reliability. By using compliant wheels, construction companies can ensure the protection of workers and the integrity of the scaffold tower, minimizing the risk of accidents or structural failures.

To illustrate the importance and benefits of high-quality scaffold wheels, let’s examine the table below:

| Benefits of High-Quality Scaffold Wheels | Features |

|---|---|

| Enhanced Safety | Designed to withstand heavy loads |

| Durability | Long-lasting, reducing the need for frequent replacements |

| Compliance | Manufactured to meet safety standards and regulations |

As shown in the table, high-quality scaffold wheels provide a range of benefits, including enhanced safety, durability, and compliance with industry standards. These wheels are an investment in the efficient and secure operation of construction projects.

Choosing the Right Scaffold Tower Wheels

When it comes to selecting the right scaffold tower wheels, there are several factors to consider. These include load capacity, wheel size, and compatibility with the scaffold tower. Properly assessing these factors ensures the wheels meet the specific requirements of your construction project and provide optimal performance and safety.

Firstly, consider the load capacity of the scaffold tower wheels. This refers to the maximum weight that the wheels can support. It is essential to choose wheels with an adequate load capacity to ensure the tower remains stable and secure during use. Be sure to consider the weight of materials, equipment, and workers when determining the required load capacity.

Next, wheel size plays a crucial role in maneuverability and stability. Larger wheels generally offer better stability and mobility compared to smaller ones. However, it is important to ensure that the wheel size is compatible with the scaffold tower. Check the manufacturer’s specifications and guidelines to determine the appropriate wheel size for your tower.

Additionally, compatibility is key when selecting scaffold tower replacement wheels. Different scaffold towers may have specific requirements for wheel attachments. Make sure the wheels you choose are compatible with the existing structure or can be easily integrated with the tower. Consult the manufacturer or a professional supplier for guidance in selecting compatible replacement wheels.

Consulting with a professional or supplier is highly recommended throughout the selection process. They can provide valuable expertise and insight into choosing the right scaffold tower wheels. Their knowledge of the industry and familiarity with various wheel options can help you make an informed decision that aligns with your project’s needs.

Benefits of Choosing the Right Scaffold Tower Wheels

Choosing the right scaffold tower wheels ensures optimal performance and safety on construction sites. It minimizes the risk of accidents caused by wheel failure or instability. With wheels that have the appropriate load capacity, size, and compatibility, you can confidently move and position the scaffold tower as needed, improving efficiency and productivity.

Comparison of Scaffold Tower Wheel Options

| Wheel Type | Load Capacity | Wheel Size | Compatibility | Features |

|---|---|---|---|---|

| Heavy-Duty Wheels | Up to 1000 lbs | 8 inches | Compatible with most scaffold towers | Sturdy and durable construction for heavy loads |

| Adjustable Caster Wheels | Up to 800 lbs | 6 inches | Compatible with adjustable scaffold towers | Provides flexibility in positioning and maneuverability |

| Replacement Wheels | Varies | Depends on specific replacement | Compatibility varies by manufacturer | Made to fit specific scaffold tower models |

Table: Comparison of Scaffold Tower Wheel Options. This table provides an overview of different scaffold tower wheel types, including their load capacity, wheel size, compatibility, and notable features. Use this information as a starting point to help you make an informed decision when choosing the right wheels for your scaffold tower.

Ensuring Safety with Scaffold Tower Wheels

Safety is paramount when it comes to using scaffold tower wheels. The scaffold wheel locking mechanism and scaffolding wheels with brakes are essential features that contribute to a secure working environment. Properly locking the wheels before climbing or using the scaffold tower eliminates the risk of accidental movement or instability.

Regular inspections and maintenance of the scaffold wheel locking mechanism and wheels themselves are crucial to ensure their proper functioning. This includes checking for any wear and tear, loose bolts, or other signs of damage that may compromise the reliability of the wheels and their locking mechanisms.

Alongside inspections, it is important to adhere to safety guidelines and regulations to further enhance safety on-site. This includes keeping the scaffold tower level and stable, following weight capacity limits, and avoiding the use of additional items on top of the scaffold that may cause instability.

By prioritizing safety and following these precautions, construction workers can confidently work at heights with scaffold tower wheels, knowing that the wheels’ locking mechanism and braking system are reliable and effective in preventing accidents.

Safety Checklist for Scaffold Tower Wheel Maintenance

| Checklist Item | Action |

|---|---|

| Inspect scaffold wheel locking mechanisms | Ensure proper functionality, tighten any loose bolts |

| Inspect scaffold wheels | Check for wear and tear, replace if necessary |

| Ensure scaffold tower is level | Use a spirit level to confirm stability |

| Follow weight capacity limits | Do not exceed the recommended load capacity |

| Avoid adding extra items to the scaffold | Avoid instability and maintain a clear working area |

By implementing these safety measures and prioritizing regular maintenance, construction sites can ensure the safety and well-being of their workers who rely on scaffold tower wheels for smooth and secure movement throughout their projects.

Conclusion

Scaffold tower wheels are essential components that significantly contribute to the smooth operation of construction projects. These wheels enable reliable mobility and secure positioning of scaffold towers, ensuring the safety and efficiency of workers on-site. By carefully selecting high-quality scaffold tower wheels and utilizing proper locking mechanisms, construction professionals can confidently move and position scaffold towers with ease.

One of the key advantages of mobile scaffold tower wheels is the convenience they offer. These wheels allow construction workers to effortlessly move the tower from one location to another without the need for disassembly. This not only saves time but also increases productivity on-site. Additionally, mobile scaffold tower wheels provide flexibility in adjusting the height and position of the tower, making it easier to access hard-to-reach areas.

Choosing the right scaffold tower wheels is crucial in ensuring optimal performance and safety. Factors such as load capacity, wheel size, and compatibility with the scaffold tower should be considered during the selection process. It is advisable to consult professionals or suppliers to ensure the appropriate wheels are chosen for specific construction requirements. Adhering to safety guidelines, such as proper locking of wheels and regular inspections, further enhances the safety of scaffold tower operations.

In conclusion, scaffold tower wheels are vital components that contribute to the successful completion of construction projects. By utilizing high-quality and properly selected wheels, construction professionals can maximize efficiency, convenience, and safety in their work. Scaffold tower wheels are a valuable investment that enables seamless mobility and stability, ultimately ensuring a successful outcome of construction endeavors.

FAQ

What are scaffold tower wheels?

Scaffold tower wheels are essential components that provide mobility and easy movement for scaffold towers on construction sites.

What types of scaffold tower wheels are available?

There are heavy-duty scaffold wheels designed for supporting heavy loads, as well as adjustable scaffold caster wheels for easy maneuverability and positioning.

What features do scaffold wheel locking mechanisms have?

Scaffold wheel locking mechanisms ensure stability and safety by preventing the wheels from moving. Scaffolding wheels with brakes allow for secure positioning of the scaffold tower.

What are the benefits of mobile scaffold tower wheels?

Mobile scaffold tower wheels enable easy mobility and save time and effort by allowing workers to move the tower without disassembling it. They also provide flexibility in adjusting the height and position of the tower.

Why is it important to use high-quality scaffold wheels?

High-quality scaffold wheels are designed to withstand heavy loads, provide stability, and meet safety standards. They are durable, reducing the need for frequent replacements.

How do I choose the right scaffold tower wheels?

Key factors to consider when choosing scaffold tower wheels include load capacity, wheel size, and compatibility with the scaffold tower. Consulting with a professional or supplier is recommended.

How can I ensure safety when using scaffold tower wheels?

Properly locking the wheels before climbing or using the scaffold tower is crucial. Regular inspections and maintenance of the wheels and locking mechanism are also important for safety.

Efficient Scaffold Hoist Solutions for Work Sites

Scaffold hoists are essential lifting equipment used in construction sites for efficient material handling….

Beam Clamp Solutions for Secure Installations

Beam clamps are versatile solutions for secure lifting and installations. They provide a secure hold…

Scaffolding Podger: Essential Tool for Rigging

A scaffolding podger, also known as a podger wrench, is an indispensable tool in the construction industry….

Unveil Your Style with a Reveal Tie scaffolding

A Reveal Tie is a unique accessory that adds a touch of elegance and sophistication to any ensemble….

Ultimate Guide to Base Jack Tool Uses & Tips

A base jack tool is an essential tool in construction and scaffolding projects. It provides stability…

No posts found