Phone:

(+65)8319-0742

Scaffolding is more than just a tool for builders. It’s a symbol of change in art, design, and city planning. It helps shape buildings and how we see our cities. From ancient times, like the pyramids, to modern bamboo scaffolds in Asia, it mixes old wisdom with new needs.

Over time, scaffolding has grown, using new techniques and materials for safety. Its parts work together to make a strong, safe place for workers to do their jobs well.

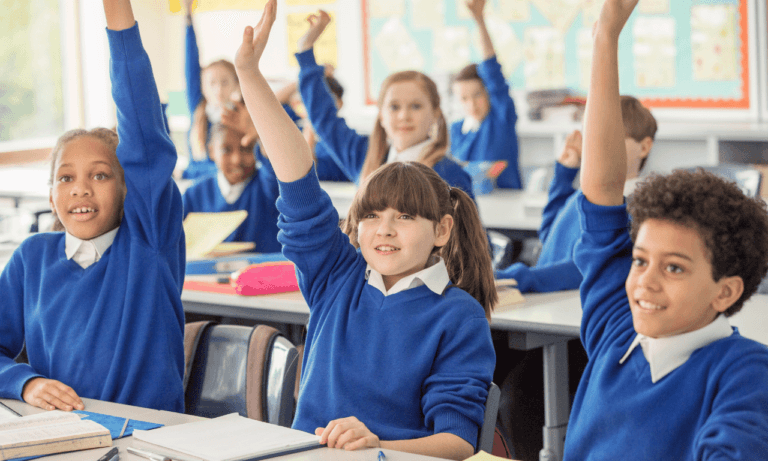

Studies show that scaffolding helps students learn better when done right. A study found that 90% of teachers believe in scaffolding and tailoring lessons. Also, 75% use modeling, and 60% of students gain from think-alouds to grasp complex ideas.

Key Takeaways

- Scaffolding changes how we see and build our world

- Modern scaffolding ensures safety with new techniques and materials

- Its parts create a secure place for construction work

- Good scaffolding boosts learning outcomes

- Teachers see scaffolding as a key teaching method

The Fundamentals of Scaffolding

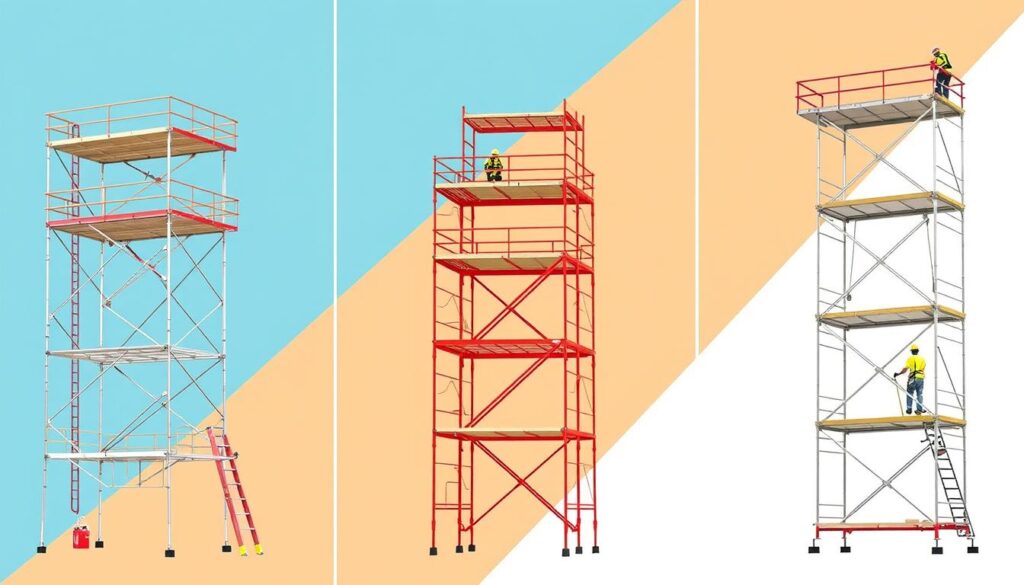

Scaffolding is a temporary setup that helps workers reach high places safely during projects. It’s key in the construction world for keeping workers safe and working well. This idea has been around for a long time, with early uses seen in ancient times. Now, scaffolding has changed a lot to fit today’s complex building needs.

The scaffolding installation process puts together different parts to make a safe place for workers. These parts work together to spread out the weight and keep the work area safe. Knowing about scaffolding is important for anyone in the building industry, like contractors, site managers, and workers.

Components of a Scaffolding System

A scaffolding system has many important parts that make it strong and safe. These include:

- Standards: These are vertical tubes that hold up the scaffold and keep it stable.

- Ledgers: These are horizontal tubes that connect to the standards at right angles, making the platform shape.

- Transoms: These are horizontal tubes that support the decking boards and link ledgers together.

- Couplers: These are fittings that connect tubes, letting the scaffold be shaped as needed.

- Base Plates: These are flat plates under the standards to spread the weight evenly on the ground.

- Guard Rails: These are horizontal tubes on the standards, giving workers on the platform protection from falling.

Each part of the scaffolding is key to making it stable and safe. Choosing and putting these parts together right is crucial for a reliable and safe work area.

Types of Scaffolding Materials

Scaffolding materials have changed a lot over time, thanks to new technology and manufacturing. Now, there are many types of scaffolding materials, each with its own benefits and uses:

- Steel: Steel is the top choice for scaffolding because it’s strong, lasts a long time, and can handle tough weather.

- Aluminum: Aluminum scaffolding is light and easy to move, perfect for projects that need quick setup and teardown. It also doesn’t rust, making it great for outdoor use.

- Wood: Wooden scaffolding is not as common today but still used in some traditional building methods. It’s light, easy to handle, but needs regular upkeep and can’t hold as much weight as metal scaffolding.

- Bamboo: Bamboo scaffolding is mainly used in Asia because it’s cheap and plentiful. It’s light, bends easily, and simple to set up but can’t carry as much weight or last as long as metal scaffolding.

Choosing the right scaffolding materials depends on the project’s needs, how much weight it will hold, the weather, and the budget. Picking the right material is key to making sure the scaffolding is safe and works well.

“Scaffolding is not just about providing access; it’s about creating a safe and efficient working environment for our workers. By understanding the fundamentals of scaffolding and selecting the right components and materials, we can ensure that our projects are completed on time, within budget, and most importantly, without compromising the safety of our team.”

– John Smith, Construction Manager

Scaffolding Safety: A Top Priority

In the construction world, safety is key. Scaffolding is crucial for keeping workers safe at heights. Safety experts follow strict rules and best practices to make sure work areas are safe. This focus on safety saves lives and builds a culture of care and excellence.

Safety Regulations and Standards

Scaffolding safety follows strict rules and standards. OSHA (29 CFR 1926.451) sets clear guidelines for scaffolding, including suspended and traditional types. These rules make sure scaffolds are safe and strong. Following these rules is essential for a safe work place.

Best Practices for Scaffolding Safety

Experts follow best practices for scaffolding safety. They check scaffolds often to spot and fix dangers quickly. Keeping scaffolding in good shape is key. Workers get the right training to stay safe on scaffolds.

They also wear safety gear like harnesses and helmets. It’s important to watch the weight on scaffolds to avoid collapses.

“Our commitment to scaffolding safety is unwavering. We prioritize the well-being of our workers above all else, and that starts with rigorous adherence to safety regulations and best practices.” – John Smith, Scaffolding Safety Manager

Common Scaffolding Hazards and How to Avoid Them

Scaffolding work comes with risks like falls and electrocution. But, these risks can be lowered with careful planning and safety steps. Haki Bespoke Platforms designs scaffolding that focuses on safety and efficiency. Using special scaffolding and safety rules helps reduce accidents and keeps workers safe.

| Common Scaffolding Hazards | Prevention Measures |

|---|---|

| Falls | Use of fall protection equipment, such as harnesses and guardrails |

| Falling Objects | Secure tools and materials, use toe boards and debris nets |

| Electrocution | Maintain safe distances from power lines, use non-conductive materials |

| Structural Failures | Regular inspections, proper scaffolding maintenance, adherence to load limits |

By staying alert and tackling safety issues, we can make a safe work place for everyone. With rules, best practices, and a strong safety focus, the scaffolding industry helps construction projects grow safely. It keeps workers safe as they build structures.

How Does Scaffolding Work?

Scaffolding is a marvel that lets workers reach high places and build big structures. It’s all about safe, stable, and efficient design. Learning how scaffolding works shows us the skill and knowledge behind these important tools.

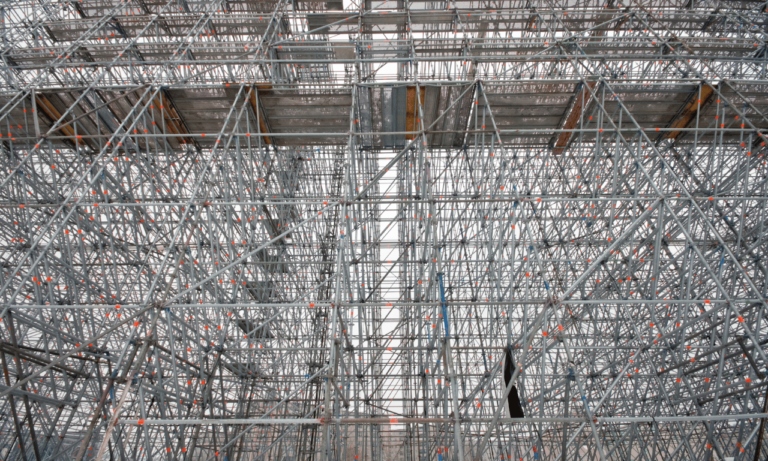

Scaffolding Design and Engineering Principles

The design and engineering of scaffolding are key to its success. It must hold heavy loads, resist side forces, and be a stable place for workers. Engineers figure out how much weight the scaffolding needs to hold, making sure it can do the job.

Triangulation is a big part of scaffolding design. Diagonal bracing makes scaffolding stable and strong. This helps it stand up to wind and heavy loads. Formwork scaffolding uses these ideas to hold up wet concrete until it sets.

Load Distribution and Weight Capacity

Evenly spreading the weight is crucial in scaffolding design. Engineers make sure workers, tools, and materials are balanced. They use ledgers, transoms, and decking to spread the load evenly, avoiding overload.

“Scaffolding can withstand more than 500 lbs of weight, providing a secure platform for construction workers.”

The strength of scaffolding depends on its materials and design. Steel scaffolding is strong for heavy jobs. Aluminum scaffolding is light and easy to move, good for lighter tasks.

Scaffolding Erection and Dismantling Processes

Putting up and taking down scaffolding is done carefully for safety and efficiency. It starts with the base and adds levels up, securing each part as it goes. This way, the scaffolding stays stable as it gets taller.

When taking it down, they start from the top and work down. This careful method lowers the risk of accidents and keeps the scaffolding stable during dismantling.

| Scaffolding Component | Function |

|---|---|

| Standards | Vertical poles that support the weight of the scaffolding |

| Ledgers | Horizontal tubes that connect the standards and provide support for the decking |

| Transoms | Cross-bracing that provides additional stability and supports the decking |

Following the right steps to put up and take down scaffolding keeps it safe and reliable on the job site.

Knowing how scaffolding works is key for construction pros. By using good design, spreading loads right, and following the right steps, scaffolding lets teams work safely at heights. It turns building ideas into real structures.

Scaffolding in Construction: Supporting Growth and Development

Scaffolding is key in construction, making projects safe and efficient. It’s used everywhere, from busy cities like Hammersmith to beautiful Essex. Metal scaffolding components keep workers safe and help construction move smoothly.

In places like Brentwood, scaffolding links old and new. It helps build new things while keeping the area’s history. Scaffolding pros follow strict safety rules and best practices. This keeps workers safe and protects the area.

Scaffolding’s design shows how smart and skilled the construction industry is. It’s all about making sure it can hold weight and is safe. Every step of setting it up or taking it down is done carefully. This makes sure construction goes well with scaffolding’s strong support.

Scaffolding is vital for reaching high places safely. It lets us build big projects while keeping everyone safe. We’re always finding new ways to use scaffolding, keeping our buildings safe and sound.

Scaffolding helps communities grow and build with confidence. It will keep playing a big part in making our future cities and towns. With scaffolding, we’re not just building buildings. We’re building a future where new ideas and old traditions can live together.