Phone:

(+65)8319-0742

Fraco is a top name in the construction world, known for its fraco scaffolding and building materials. They’ve changed the game with their innovative solutions. Their focus on safe and efficient projects has made them stand out.

Fraco is all about building strong relationships. They believe in connecting with people to create a space where everyone can share ideas and trust each other. This way, they can offer custom solutions that fit each project perfectly, making sure everyone is happy.

Fraco doesn’t just stop at special projects. They’re always looking to get better at what they do. They use the latest technology and keep their team up-to-date with the latest in the industry. This keeps them at the forefront of providing top-notch scaffolding systems.

Key Takeaways

- Fraco is a trusted provider of innovative fraco scaffolding and fraco building materials

- The company specializes in developing safe and efficient construction projects

- Fraco’s success is built on strong relationships with customers and stakeholders

- Continuous improvement in manufacturing and customer service is a core value

- Fraco’s innovative spirit drives the development of state-of-the-art fraco scaffold systems

Fraco’s Commitment to Innovation

Fraco Scaffold is a leader in the construction world because of its dedication to innovation. They have an innovative spirit that shows in everything they do. This spirit helps them provide cutting-edge solutions for their clients’ needs.

Engineered Solutions for Unique Projects

Fraco tackles challenges that others avoid. Their skilled engineers and project managers create custom solutions for special projects. This makes Fraco the top choice for clients with complex needs.

“Fraco’s ability to engineer solutions for our unique project requirements has been invaluable. Their expertise and commitment to innovation have consistently impressed us.” – Sarah Thompson, Construction Manager

Continuous Improvement in Manufacturing and Customer Service

Fraco’s innovation goes beyond engineering. They always look for ways to improve their manufacturing and customer service. By making their assembly lines more efficient, they’ve cut down production time and improved quality.

They also focus on making customer service better. This means clients get quick and accurate answers to their questions.

| Aspect | Fraco’s Approach | Industry Standard |

|---|---|---|

| Engineering Expertise | Specialized team for uncommon projects | Limited experience with unique challenges |

| Manufacturing | Continuous assembly line improvements | Infrequent process updates |

| Customer Service | Streamlined request processing | Varying response times and accuracy |

Fraco Scaffold leads the construction industry with its innovative approach. Their focus on engineering expertise, special project management, and improving manufacturing and customer service makes them stand out. They are a trusted partner for those looking for innovative construction solutions.

Reliable Support and Expertise

Fraco Products Ltd. has been a trusted partner for over 30 years. It serves construction pros in North America and Europe. The company offers a wide range of services, including work platforms and construction hoists. They also provide industrial elevators and transportation platforms.

Comprehensive Action Plans

Fraco’s success comes from detailed action plans. These plans ensure projects run smoothly from start to finish. The team works closely with clients to create solutions that fit their needs.

By focusing on project management, Fraco avoids common project delays. This approach helps projects finish on time and within budget.

Rigorous Training Standards

Fraco invests in employee training to ensure safety and efficiency. The company has strict training rules. This makes sure every team member knows how to do their job well.

Fraco’s focus on education makes it a top employer. This has earned it a great reputation in the industry.

“Fraco’s training program has been instrumental in my growth as a professional. The company’s focus on safety and best practices has given me the confidence to tackle even the most challenging projects.” – John Smith, Fraco Technician

Ensuring Safety and Regulatory Compliance

Safety is a top priority for Fraco. The company follows strict safety rules and maintains equipment well. This ensures all installations meet high standards.

Fraco works with the best suppliers and service providers. This guarantees the safety and reliability of its products and services.

| Safety Measure | Fraco’s Approach |

|---|---|

| Equipment Maintenance | Regular inspections and preventive maintenance to ensure optimal performance and longevity |

| Installation Procedures | Strict adherence to manufacturer guidelines and industry best practices |

| Employee Training | Comprehensive safety training for all employees, including regular refresher courses |

| Regulatory Compliance | Continuous monitoring of local, state, and federal regulations to ensure full compliance |

Fraco’s focus on safety and compliance has won customer trust. The company’s success in project execution and customer service is well-known. This is why Fraco has received many five-star ratings and positive testimonials.

Prioritizing Human Relationships

At Fraco, we believe that our success comes from strong human connections. We see our relationships with customers and employees as long-term partnerships. These partnerships are built on trust, respect, and shared goals.

By creating a collaborative environment, we drive innovation and excellence. This is thanks to the strong ties we build with all stakeholders.

Long-Term Partnerships with Customers and Employees

We are committed to long-term relationships with our customers. We take the time to understand their unique needs and challenges. This helps us develop customized solutions that deliver lasting value.

Our dedicated team provides ongoing support and expertise. This ensures our customer partners have the resources they need to succeed.

We also invest in our employee partners. We recognize their talent, passion, and dedication as key to our growth. We offer comprehensive training and opportunities for professional development.

This empowers our team members to reach their full potential. We create a positive and inclusive workplace culture. This attracts and retains top talent who share our vision and values.

Fostering Strong Ties Among Stakeholders

At Fraco, we know our success is tied to our stakeholders’ success. We work to build strong ties among employees, customers, suppliers, and communities. By promoting open communication and collaboration, we create a network of partners who support each other’s success.

“Our expertise in materials and construction solutions is enhanced by our deep appreciation for the importance of human relationships. We believe that by prioritizing the needs and aspirations of our partners, we can achieve great things together.” – Fraco Founder

Through our focus on long-term relationships and strong ties, Fraco has become a trusted partner in the construction industry. As we grow and innovate, we believe our human connections will be the key to our success.

Safety on Mast-Climbers

Fraco is serious about mast-climber safety. They care about workers’ health and well-being over time. They use safety measures and training to prevent accidents and keep workers safe.

Fraco’s work platforms are stable, flexible, and safe. They also save money by up to 36%. The platforms meet safety standards and can reach heights of 38 feet without anchors.

They are fast, lifting 3 feet per minute. But, they need regular checks as shown in Fraco’s guide.

Fraco teaches workers how to use the platforms safely. They must follow rules and get permission to work. A trained person checks the equipment at the start of each day.

They warn against overloading the platform. All checks and maintenance must follow the maker’s guide.

Fraco also offers circular scaffolding like the BRIO system. These systems make work areas safe and help prevent accidents.

Addressing Immediate Risks and Long-Term Health Concerns

Fraco looks at safety from all angles. They aim to make work safer and healthier for everyone.

Some common dangers include:

- Lack of training

- Improper use

- Falls

- Inadequate guardrail protection

- Collapses

- Improper planking

- Inadequate inspection

To avoid these dangers, Fraco suggests:

- Always install guardrails and mast guards, ensuring access gates and other access locations are protected.

- Use all required personal fall protection equipment during erection, dismantling, or when a fall hazard exists.

- Do not bypass or override normal operating controls for the MCWP, including safety devices.

- Conduct hazard checks for overhead obstructions, building protrusions, high voltage lines, insufficient base support, drop-offs, debris, and other unsafe conditions.

- Do not alter ties, platform, or base without written authorization from the manufacturer and Competent Person.

Fraco also thinks about long-term worker health. They design their equipment to be ergonomic. They teach workers to use proper posture and techniques to avoid injuries.

“At Fraco, we believe that a safe and healthy workforce is the foundation of a successful construction project. By prioritizing both immediate safety and long-term health, we aim to create a working environment that allows our customers and their employees to thrive.”

| Safety Feature | Benefit |

|---|---|

| Meets ANSI and OSHA safety requirements | Ensures compliance with industry standards |

| Periodic maintenance according to user’s guide | Maintains equipment in optimal condition |

| Proper training and authorization for personnel | Reduces risk of accidents due to human error |

| Pre-start inspection by Competent Person | Identifies potential issues before operation |

| Supervision by Competent Person during operation | Ensures proper use and adherence to safety protocols |

Fraco is dedicated to making work safer and healthier for everyone. They focus on both immediate safety and long-term health.

Fraco EXO: Exoskeletons in Construction

Exoskeleton technology is now in construction, thanks to Fraco. They’ve made the Fraco EXO for construction workers. It aims to make work easier and safer.

Adapting Exoskeleton Technology for the Industry

Fraco EXO shows how technology can help construction. It’s based on military and medical exoskeletons. The final version is almost ready for 2021.

The Fraco EXO fits each worker perfectly. It has different parts for a snug fit. This means workers can wear it all day without getting tired or uncomfortable.

Enhancing Worker Comfort and Efficiency

The Fraco EXO makes work easier and safer. It supports up to 26lbs per arm. This helps with lifting, reducing strain on workers.

It also has a long battery life. The battery lasts days, so workers don’t have to recharge it often. This keeps them working without interruptions.

| Delivery Month | Number of Exoskeletons |

|---|---|

| September 2021 | 50 |

| October 2021 | 50 |

| November 2021 | 50 |

The Fraco EXO is light and easy to wear. It takes just a minute to adjust. This saves time and keeps work flowing smoothly.

Exoskeletons like the Fraco EXO can solve labor shortages. They help prevent injuries and let workers work longer. The market for exoskeletons is expected to grow a lot, reaching $20 billion by 2035.

The exoskeleton provides a sense of security by distributing weight to the muscles, reducing the risk of back injuries.

Exoskeletons are becoming common in construction. Training programs will include them. The Fraco EXO is easy to use and doesn’t need much training. It’s a practical solution for the industry.

ACT-8 Mast Climber: Effortless Access to New Heights

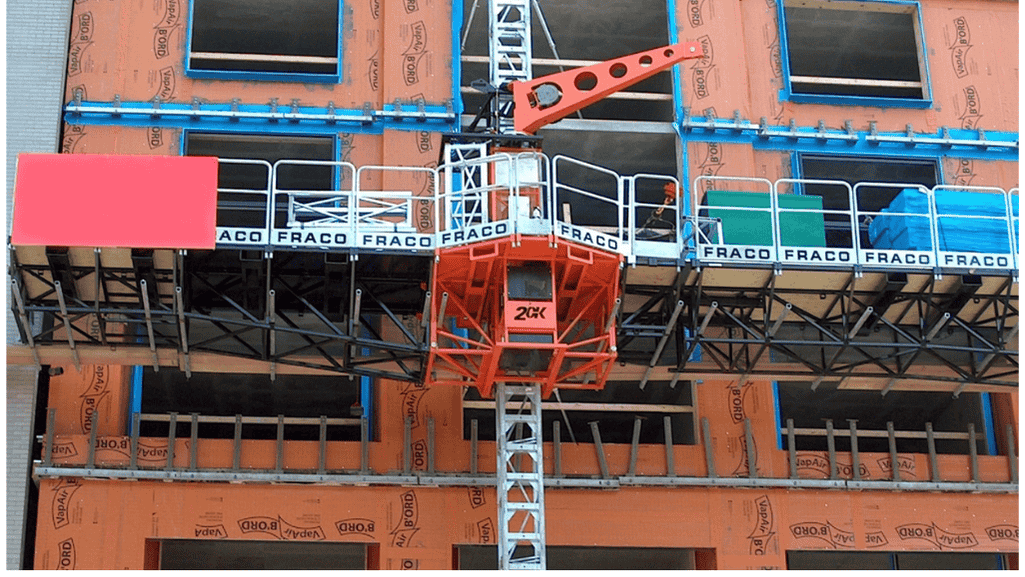

The Fraco ACT-8 mast climber is a game-changer in construction. It gives professionals easy access to high places on tough projects. This electric platform is perfect for building, maintenance, and renovation, without disturbing the area.

It has top safety features and precise control. This means smooth movements and fewer accidents. Plus, it’s quiet and uses no fossil fuels, cutting down on pollution.

Fraco’s mast climbers, like the ACT-8, FRSM-20K, and FMC-3, are leaders in the field. They can lift heavy loads and reach high, making projects more efficient. This is seen in North America and Europe.

The ACT-8 and FRSM-20K are great for complex jobs. They can go up to 125 feet and carry a lot, making them perfect for many projects. This includes high-rise buildings and infrastructure works.

These mast climbers have been used in many projects. For example, they helped restore the St. Joseph Oratory in Montreal. They also helped build the Fabrik8 commercial building. These examples show how they offer safer and more efficient ways to work at heights.

| Fraco Mast Climber Model | Maximum Payload | Maximum Height | Travel Speed |

|---|---|---|---|

| ACT-8 (Twin Mast) | 16,000 lbs | 125 feet | 39 feet per minute |

| FRSM-20K | 10,000 lbs per mast | 500 feet | – |

| FMC-3 | 10,000 lbs per mast | 500 feet | – |

Mast climbers are key in construction. In the U.S., thousands use them daily. But safety is crucial, as shown by past incidents. Fraco’s ACT-8 ensures workers can reach high places safely and efficiently.

Fraco leads in construction tech and safety. The ACT-8 mast climber shows their commitment to innovation. It helps professionals work at heights with confidence and care. For more on construction tech, check out our guide on formwork and shuttering scaffolding.

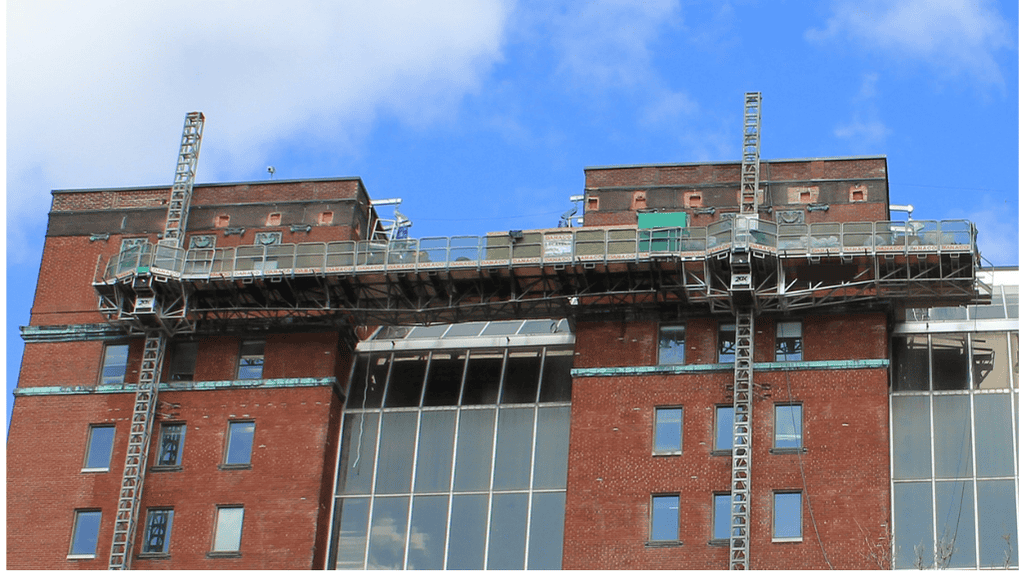

Fraco’s Common Tower System (CTS)

Fraco’s Common Tower System (CTS) changes elevator installation in new and old buildings. It’s flexible and adapts to different needs, keeping the building’s look intact. This system cuts down on the need for big holes in the building, making it easier to work and move things around.

Flexible and Adaptable Elevator Installation

The CTS is made to be changed to fit any project. It’s easy to set up and take down, saving time and money. This flexibility also means it can change as the project grows, keeping everything running smoothly.

Minimizing Disruption to Building Envelope

The CTS makes fewer and smaller holes in the building, keeping it strong and safe. It stops water and heat from getting in, saving energy. Its small size means it blends well with the building’s outside, looking neat and tidy.

Maximizing Access for Personnel and Materials

The CTS can have up to three dual hoists, making it easier to move people and things. This speeds up work, making the site more efficient. The hoists are placed smartly to avoid delays and keep everyone moving.

| Feature | Benefit |

|---|---|

| Up to three dual hoists | Significantly enhances access for personnel and materials |

| Three-hoist configuration | Minimizes building footprint to just 16 feet |

| Safe Build Technology (SBT) | Prioritizes worker safety with lightweight aluminum components |

| Separate landings outside the building | Offers remote landings to free up valuable interior space |

| Efficient high-rise construction | Allows lower floors to be fully fitted out while upper floors are under construction |

The CTS also has features like separate landings outside, making more space inside. These remote landings give extra access without messing up the inside. It lets lower floors be ready while upper floors are still being built, speeding up the whole project.

Fraco’s Common Tower System has changed elevator installation in our projects. Its flexibility, adaptability, and ability to maximize access while minimizing disruption have been game-changers for our construction process.

CTS: Prioritizing Safety with Safe Build Technology (SBT)

Fraco’s Common Tower System (CTS) uses Safe Build Technology (SBT) to focus on safety. It has lightweight aluminum parts and simple assembly. This makes the installation safe and efficient, reducing hazards on-site.

Simplicity in Assembly

The CTS is designed to be easy to assemble. Its parts fit together well, cutting down on complex steps and errors. This makes the process faster and safer, ensuring the structure is built right.

Intuitive Design for Easy Installation

The CTS has a design that’s easy to follow, like a Lego set. Its parts are made to connect easily, with clear signs and a logical order. This makes it simple for workers to assemble the system safely and quickly.

Secure Connections and Reduced Loose Parts

The CTS focuses on strong connections for stability. It uses special joints that are reliable. This means no loose parts like bolts, which could be lost or cause safety issues.

Also, the CTS needs fewer tools during assembly. This makes the process smoother and lowers the chance of accidents from tools.

| Safe Build Technology (SBT) Feature | Benefit |

|---|---|

| Lightweight aluminum components | Easier handling and reduced strain on workers |

| Simple assembly process | Faster installation and reduced risk of errors |

| Intuitive, “Lego-like” design | Quick learning curve and confident assembly |

| Secure connections (notched slots, spring pin latches, linked pins) | Enhanced stability and reduced risk of component failure |

| Minimized loose parts and tools | Streamlined installation and reduced tool-related accidents |

Fraco’s CTS with Safe Build Technology shows its dedication to safety. It combines lightweight materials, easy assembly, and secure connections. This makes the system efficient and safe for everyone using it.

Fraco Scaffold: Revolutionizing Construction Flexibility

Fraco’s Common Tower System (CTS) is changing the construction game. It brings unmatched flexibility and efficiency. This scaffold system offers many benefits that make construction better, cheaper, and safer on tall buildings.

Remote Landings to Optimize Interior Space

The CTS lets you create remote landings outside the building. This saves valuable space inside, helping finish interior work sooner. It makes construction faster, as both inside and outside work can happen at the same time.

Reducing Building Footprint with Multi-Hoist Configurations

The CTS can have multiple hoists, cutting down the space needed for scaffolding. With three hoists, the space needed is just 16 feet. This saves space and makes the construction site more efficient.

Enabling Efficient High-Rise Construction

Fraco’s CTS is great for tall buildings, where old scaffolding methods are slow. It creates a sealed area, letting lower floors be finished while upper floors are built. This makes construction faster, saves on labor, and gets projects done sooner.

| Benefit | Impact |

|---|---|

| Reduced man-hours | Up to 50% reduction, resulting in significant labor cost savings |

| Shortened project timelines | Earlier project completions and reduced overhead costs |

| Optimized workforce utilization | Labor savings allow for boosted overall productivity |

| Unparalleled access and flexibility | Reduced labor requirements for facade work |

| Streamlined processes | Rapid adjustments and improved safety in industrial projects |

Fraco’s CTS is a game-changer for high-rise construction. It focuses on flexibility, space optimization, and efficient workflows. Fraco is leading the way to faster, safer, and cheaper construction.

Conclusion

Fraco scaffold has changed the construction world with its new ideas. It focuses on making work safer and more efficient. The ACT-8 mast climber lets workers reach new heights easily. The Common Tower System (CTS) makes installing elevators flexible and adaptable.

Fraco’s products aim to keep the building safe while giving workers easy access. The CTS has Safe Build Technology (SBT) for extra safety. This technology makes setting up scaffolding simple and secure.

Fraco’s scaffolding systems are flexible, allowing for remote landings and multi-hoist setups. This makes high-rise building more efficient. It also saves space and reduces the building’s footprint.

Fraco is always improving, not just its products but also its service. It works hard to support its clients with reliable help and knowledge. The company focuses on safety and follows all rules to be a trusted partner in construction.

Fraco builds strong relationships with its customers and employees. This helps it stay a leader in the construction field.

Fraco is always ready for new challenges in construction. It has introduced the Fraco EXO exoskeleton to make work more comfortable and efficient. This shows Fraco’s commitment to safety and worker well-being.

By always finding new solutions and focusing on safety and efficiency, Fraco is ready for any project. Its innovative construction solutions and dedication to its clients make it a key player in the industry. Fraco is set to keep changing the construction world for many years.