Phone:

(+65)8319-0742

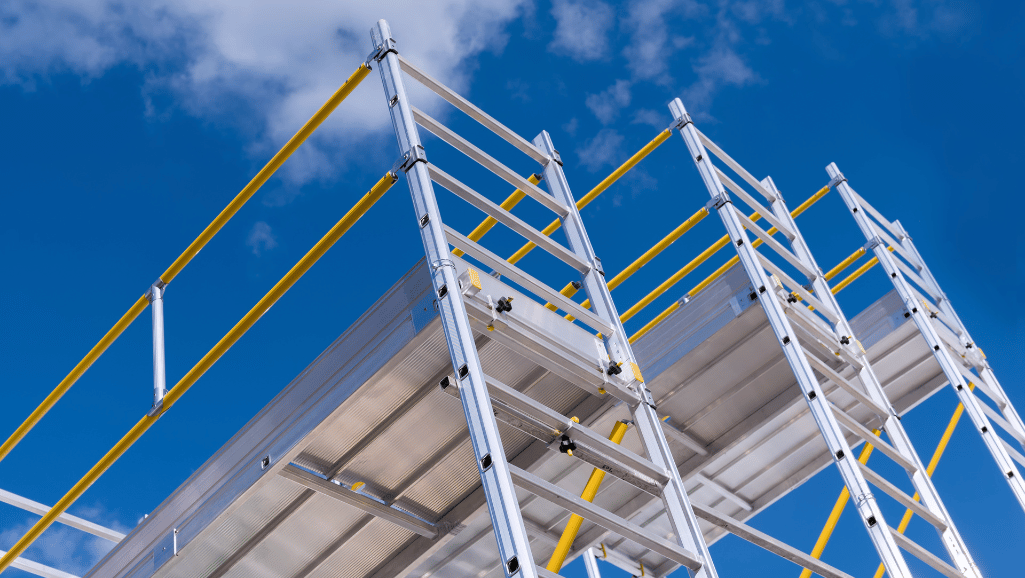

Aluminium folding scaffolds have changed the game in scaffolding. They are super portable and very durable. These systems have made setting up temporary scaffolding much easier. They are lightweight yet strong, making them very popular.

SafeSmart Access leads in scaffolding solutions with a wide range of products. They offer mobile scaffolding towers and work platforms. Their lineup includes the all-terrain stair pack and the super-compact SafeDeck scaffold. These solutions are perfect for many industries, like construction and maintenance.

Aluminium folding scaffolds are easy to move around because they’re light. Prices start at Rs 4,400 for basic models and go up to Rs 54,000 for more advanced towers. They’re a great choice because they last a long time and don’t rust, making them good for both inside and outside use.

Key Takeaways:

- Aluminium folding scaffolds offer portable and durable solutions for temporary scaffolding needs.

- SafeSmart Access provides a wide range of aluminum scaffolding products, including mobile scaffolding towers and innovative designs.

- Lightweight construction and corrosion resistance make aluminium folding scaffolds easy to transport and suitable for various environments.

- Prices for aluminium scaffolding solutions vary based on specific product types and features.

- Aluminium folding scaffolds are versatile and can be used in construction, building maintenance, industrial, and manufacturing settings.

Introduction to Aluminium Folding Scaffolds

Aluminium folding scaffolds have changed the construction world. They are lightweight, portable, and versatile for temporary work areas. They are key for safety and convenience on construction sites, vital for many professionals.

These scaffolds are made to be flexible, with various platform sizes for indoor and outdoor use. For indoor tasks, there are three platform sizes. For outdoor, there are four options. This means workers can easily find the right equipment for their job, boosting efficiency and productivity.

Aluminium folding scaffolds meet strict safety standards. They are approved under EN1004 standards, Class 3, with a load capacity of 200 kg per square meter. This ensures workers can safely do their jobs on a stable platform, reducing the chance of accidents.

| Scaffold Type | Platform Heights | Working Height Range |

|---|---|---|

| Folding Scaffolds | 0.28m to 5.6m | 2.0m to 7.6m |

| Mobile Scaffolds | 2m to 10m | 4m to 12m |

Aluminium folding scaffolds have a wide range of platform heights for different needs. Folding scaffolds adjust from 0.28 to 5.6 meters, with a working height range of 2 to 7.6 meters. Mobile scaffolds reach even higher, from 2 to 10 meters, with a working height range of 4 to 12 meters. This lets workers easily reach high areas and do tasks at various heights.

These scaffolds also have a high load-bearing capacity. For example, rolling scaffolds can hold up to 660 kg on top tiers and an extra 50% on a full-size tire. This means they can carry a total of 990 kg safely, making it easier to move materials and equipment to high places.

Alulock Scaffolding, a leading maker of aluminium folding scaffolds, offers a 5-year warranty and a 20-year delivery guarantee. This shows their commitment to quality and customer satisfaction, proving their scaffolding is durable and reliable.

Using aluminium folding scaffolds can make construction sites safer, improve worker movement, and streamline operations. These systems are a cost-effective and efficient choice for any project needing temporary elevated work areas.

Benefits of Using Aluminium Folding Scaffolds

Aluminium folding scaffolds are gaining popularity in construction for many reasons. They are lightweight, durable, and versatile. This makes them perfect for many tasks.

Lightweight and Portable Design

Aluminium folding scaffolds are much lighter than traditional scaffolds. This makes them easy to move around on job sites. Workers can move them quickly, boosting productivity by 50%.

They also set up and take down fast, helping projects finish on time. This is great for projects with tight schedules or where scaffolding needs to be moved often.

Easy Assembly and Disassembly

Setting up and taking down aluminium folding scaffolds is quick and easy. Their lightweight parts snap together securely, saving time and effort. This is perfect for projects with tight deadlines or where scaffolding needs to be changed often.

Versatile Applications

Aluminium folding scaffolds are very versatile. They can be used in many areas, such as:

- Construction and building maintenance

- Industrial and manufacturing settings

- Event and entertainment industry

- Plastering and rendering

- Electrical work and plumbing

- Roofing and form working

- Civil works and infrastructure projects

They can be used as both a stationary and suspended platform. Aluminium scaffolding can hold a lot of weight, making it safe and stable for heavy tasks.

| Brand | Product | Load Rating | Price Range |

|---|---|---|---|

| National Ladder & Scaffold Co. | Aluminum Stages | 250 lbs – 750 lbs | – |

| Werner | Aluminum Scaffolding | – | $133.78 – $581.00 |

| TURBO Scaffolding | T-LITE Mobile Towers | – | Cost-effective |

Key Features of Aluminium Folding Scaffolds

Aluminium folding scaffolds are gaining popularity in construction for their great features and benefits. They are versatile and offer many advantages for different uses. Let’s look at what makes them stand out.

Durable Aluminium Construction

Aluminium folding scaffolds are very durable. They are made from high-quality aluminium. This makes them resistant to corrosion and rust, perfect for humid areas and tough weather.

They last a long time and need less upkeep than steel scaffolds. Their strong build means they can handle many construction tasks. This makes them a reliable choice for construction sites.

Adjustable Height and Width

These scaffolds can be adjusted for different heights and spaces. For example, the XG-177A5+1 model has three heights: 120cm, 150cm, and 180cm. The handrails are at 130cm, 100cm, and 70cm. This makes them useful for many tasks and places.

Non-Slip Platform Surface

Worker safety is key when working high up. Aluminium folding scaffolds have a non-slip surface. This surface is textured for better grip, lowering the chance of falls.

The XG-177A5+1 model has a big platform for workers to move around easily. The non-slip surface and strong aluminium make a safe place to work.

Locking Casters for Stability

These scaffolds have locking casters for extra stability. They roll easily when moved but stay put when locked. The XG-177A5+1 model has a big base for stability. The locking casters and strong base make it a dependable choice for many tasks.

| Feature | Benefit |

|---|---|

| Durable Aluminium Construction | Long-lasting performance and reduced maintenance |

| Adjustable Height and Width | Adaptability to different working heights and space requirements |

| Non-Slip Platform Surface | Enhanced worker safety and reduced risk of slips and falls |

| Locking Casters for Stability | Secure and stable working platform with easy mobility when needed |

In summary, aluminium folding scaffolds are popular in construction for many reasons. They are durable, adjustable, have a non-slip surface, and are stable. These features make them a versatile solution for many tasks. They are easy to put together and work well for construction pros.

Safety Considerations When Using Aluminium Folding Scaffolds

Working with scaffolding equipment like aluminum work platforms means putting safety first. Aluminium folding scaffolds are light and easy to move, but safety steps are key to avoid accidents.

Fall protection is vital for safety. OSHA rules say you need fall protection if you’re working over ten feet high on aluminum scaffolds. The top rail should be at least 38 inches high, with a maximum of 45 inches. Crossbracing can be used as a top rail, but it must be at least 38 inches up and no more than 48 inches.

Putting together and taking apart mobile scaffold systems right is important for safety. Midrails should be halfway between the platform and the top rail, between 20 to 30 inches up. Scaffolds must hold at least four times the weight they’re meant to, and suspension scaffolds need to hold six times their weight.

Employers must teach their workers about scaffold dangers and how to use them safely. They also need to check the scaffolds before work starts. A competent person can spot hazards, fix them quickly, and make sure they’re safe.

“Safety is not just a priority; it’s a way of life on the job site. Proper training, regular inspections, and adherence to safety standards are essential when working with aluminium folding scaffolds.”

When setting up or taking down a scaffold, a trained person should check if it’s safe and use fall protection. Checking the lightweight scaffolding regularly helps spot damage or wear. If someone falls from over two meters, the scaffold must be checked every week.

For stability and safety, use well-kept castor wheels or base plates with folding work platforms. Add stabilizers when you raise the aluminum mobile scaffold tower. Also, lower it to 4 meters before moving it to avoid hitting things and risks.

By focusing on safety, giving good training, and doing regular checks, workers can use portable scaffolds safely. This helps cut down on accidents and injuries at work.

Choosing the Right Aluminium Folding Scaffold for Your Needs

Choosing the right aluminium folding scaffold is key for a safe and efficient work area. Think about what your project needs, like how much weight it must hold, the height you need to reach, the size of the platform, and its setup. Aluminium folding scaffolds vary in size and design for different jobs, from building to industrial work.

Load Capacity and Working Height

When picking an aluminium folding scaffold, look at its load capacity. Make sure it can handle the weight of workers, tools, and materials. These scaffolds can hold up to 75 pounds per square foot and meet OSHA standards for heavy-duty use. Also, think about how high you need to work. Folding scaffolding can go up to 12 feet high, fitting many tasks.

Platform Size and Configuration

The platform size and setup of your aluminium folding scaffold should fit your work and the number of workers. Mobile scaffolds come in single, double, and triple-widths. Pick a size that lets workers move safely and efficiently. Think about the shape and layout of your work area to pick the best scaffold setup.

| Scaffold Type | Platform Size | Load Capacity |

|---|---|---|

| Single-Width Tower | 0.75m x 1.8m | 225kg |

| Double-Width Tower | 1.45m x 1.8m | 450kg |

| Triple-Width Tower | 2.15m x 1.8m | 675kg |

Accessories and Add-ons

To make your aluminium folding scaffold better and safer, think about adding accessories and extras. These could be:

- Guardrails and toe boards for more safety

- Access ladders or stairways for easy climbing

- Outriggers for better stability on uneven ground

- Adjustable leveling jacks for precise height changes

By looking at your project needs and choosing the right aluminium folding scaffold, you can ensure safety, efficiency, and productivity. Always focus on quality, safety, and following the rules when picking, and think about how easy it is to set up, store, and move to get the most from your investment in construction gear.

Maintenance and Care of Aluminium Folding Scaffolds

Looking after your aluminum ladder scaffold is key to its safety and performance. Regular maintenance keeps it safe and working well. By following simple steps, your scaffold can last longer and stay secure for everyone using it.

Regular Inspections and Repairs

Checking your scaffolding before and after use is vital. Look at every part, like frames, platforms, and safety gear. Watch for damage, rust, or missing pieces that could make it unsafe.

Have experts check your scaffold to catch anything you might miss. Fixing small issues right away stops them from getting worse. For big problems, get professional help to fix or recondition it. This keeps your scaffolding safe and ready to use.

Proper Storage and Transportation

Storing and moving your scaffolding right is also important. Keep it dry and away from chemicals or extreme heat. This protects it from rust and damage.

When moving your scaffolding, secure it well to avoid damage. Use tie-downs and padding to protect it. Following the maker’s advice on storage and moving keeps your scaffolding in good shape.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Visual inspection | Before and after each use | Identifies potential safety hazards and damage |

| Cleaning | After each use | Removes dirt, debris, and corrosive substances |

| Lubrication of moving parts | Every 3 months or as needed | Ensures smooth operation and prevents wear |

| Tightening of fasteners | Every 6 months or as needed | Maintains structural integrity and stability |

| Professional inspection | Annually or as required by law | Thorough examination by qualified personnel |

Stick to a maintenance plan and handle storage and moving right. This keeps your aluminum scaffolding in top shape. It also makes the workplace safer for everyone.

Cost-Effectiveness of Aluminium Folding Scaffolds

Aluminium folding scaffolds are a smart choice for many industries like construction, industrial, and events. They are aluminum mobile scaffolds that save money and offer many benefits. This makes them a great investment for companies and contractors.

Aluminium folding scaffolds are light, which is a big plus. They are 50% lighter than steel ones, boosting work speed and efficiency. The lightest one weighs just 750 kg, perfect for tight spaces. This makes moving and setting them up quicker and cheaper.

Even though they’re light, these scaffolds are strong and safe. They don’t need much upkeep, unlike steel ones. This means they last longer and save money over time.

They’re easy to put together and take apart, saving time and money. You can adjust the platforms for different heights, making them versatile. This quick setup boosts productivity and cuts costs on construction sites.

| Scaffold Material | Weight (Single-Width) | Maintenance Requirements | Durability |

|---|---|---|---|

| Aluminium | 750 kg | Minimal | High |

| Steel | 1,500 kg | Regular corrosion prevention | High |

| Wood | Varies | Regular inspection and replacement | Low to Moderate |

When looking at aluminium folding scaffolds, think about quality, the supplier’s reputation, customization, and support after the sale. They might cost more upfront, but their long-term benefits like durability and low upkeep make them a smart choice.

Aluminium scaffolds are also recyclable, which is good for the planet and reduces waste. With the growing need for construction scaffolding systems and industrial solutions, especially in places like Saudi Arabia, choosing aluminium scaffolds is a wise move. They offer efficient and safe temporary access and work safety equipment.

Aluminium Folding Scaffold vs. Other Scaffolding Options

Choosing the right scaffolding is key for your project. Aluminium folding scaffolds are popular for their portability, durability, and versatility. Let’s see how they stack up against steel and wooden scaffolds.

Comparison with Steel Scaffolds

Steel scaffolds are known for their strength and stability. But, aluminium scaffolds have some big advantages. They are much lighter, making them easier to move and set up on site. Aluminium is up to 50% lighter than steel, cutting down on labor costs and injury risks.

Aluminium also doesn’t rust or corrode like steel can. This means it stays strong and looks good over time. It’s perfect for outdoor projects or places with lots of moisture. Lightweight scaffold towers made of aluminium are a smart choice for reliable performance and saving money over time.

Advantages Over Wooden Scaffolds

Wooden scaffolds have a long history in construction but have some big downsides. They don’t last as long because wood can rot, warp, or get infested with insects. Aluminium scaffolds, on the other hand, are much more durable.

Aluminium scaffolds are also more versatile. They can be adjusted to fit different projects. They have non-slip surfaces and locking casters for extra stability. This makes them safe for workers in various settings, from building sites to industrial areas.

| Feature | Aluminium Scaffolds | Wooden Scaffolds |

|---|---|---|

| Average Lifespan | 20+ years | 5-10 years |

| Weight Capacity per Platform | 220-275 kg | 150-200 kg |

| Maintenance Requirements | Minimal | Regular painting and treatment |

Aluminium scaffolds clearly beat wooden ones. They last much longer and are easier to handle. The non-slip surface cuts accident risks by half. With a strong weight capacity, they offer a safe way to access high places.

In summary, aluminium folding scaffolds have many benefits over steel and wooden ones. They’re light, don’t rust, versatile, and safe. Choosing aluminium scaffolding helps contractors work better, save money, and keep workers safe on all projects.

Real-World Applications of Aluminium Folding Scaffolds

Aluminium folding scaffolds are key tools in many industries. They are aluminum scaffolding solutions that are easy to move, strong, and simple to use. This makes them perfect for many tasks and projects.

Construction and Building Maintenance

In construction, aluminium folding scaffolds are vital for safe work platforms. They’re used for painting, plastering, roofing, and electrical work. Their light weight and easy to move design cuts down on setup time and boosts work speed.

For building upkeep, these scaffolds are a big help. They adjust to fit different tasks like cleaning windows, fixing facades, and checking gutters. Aluminium’s strength and resistance to rust mean these scaffolds last long, even in tough outdoor conditions.

Industrial and Manufacturing Settings

Industries use aluminium folding scaffolds for upkeep, fixes, and putting in new equipment. They give workers a stable place to reach high spots, like high ceilings or machinery. The non-slip surface and lockable wheels keep workers safe and steady.

In factories and warehouses, these scaffolds help with keeping track of inventory, organizing stock, and routine upkeep. They’re easy to move and set up, which helps keep things running smoothly and cuts down on delays.

Event and Entertainment Industry

The event and entertainment world counts on aluminium folding scaffolds a lot. They’re used for setting up stages, hanging lights, and making temporary seating. Their design lets them be quickly put together and taken apart, perfect for short events.

In theaters and concert halls, these scaffolds hold up sound and lighting gear. They adjust to different heights and can hold a lot of weight, keeping technicians safe. They’re also easy to move, making them great for different events.

Outdoor events like festivals and fairs also use these scaffolds. They make stable platforms for vendors, displays, and temporary setups. Aluminium’s weather resistance means these scaffolds can handle the elements, keeping everyone safe and sound.

Aluminium folding scaffolds are vital in many areas of life. They’re used in construction, maintenance, industry, and entertainment for their portability, strength, and safety. Their design makes them a top choice for professionals who need reliable access solutions. These scaffolds are adaptable and strong, helping workers do their jobs safely and effectively across many fields. Whether it’s renting aluminum scaffolding or using it for a project, these tools are key for many tasks and projects.

Conclusion

Aluminum folding scaffolds have changed the game in construction, industry, and events. They offer portability, durability, and versatility. Their lightweight design makes them easy to move around, cutting down on the need for heavy lifting gear.

These scaffolds are stronger yet lighter than traditional steel ones. They let you build taller scaffolding safely. This makes them a top choice for many projects.

Setting up and taking down these scaffolds is easy, even for one person. This saves time and money. The wheels lock in place for safety and stability. Plus, they fold up easily, making them simple to store and transport.

Choosing top-notch aluminum folding scaffolds, like those from FMA Factory in Qatar, means you meet safety standards. They come with safety features like guardrails and non-slip surfaces. This lowers the chance of accidents.

By focusing on safety, businesses can work better, spend less, and keep their workers safe. Aluminum folding scaffolds are changing how we do elevated work in many fields. They offer great value and performance.