Phone:

(+65)8319-0742

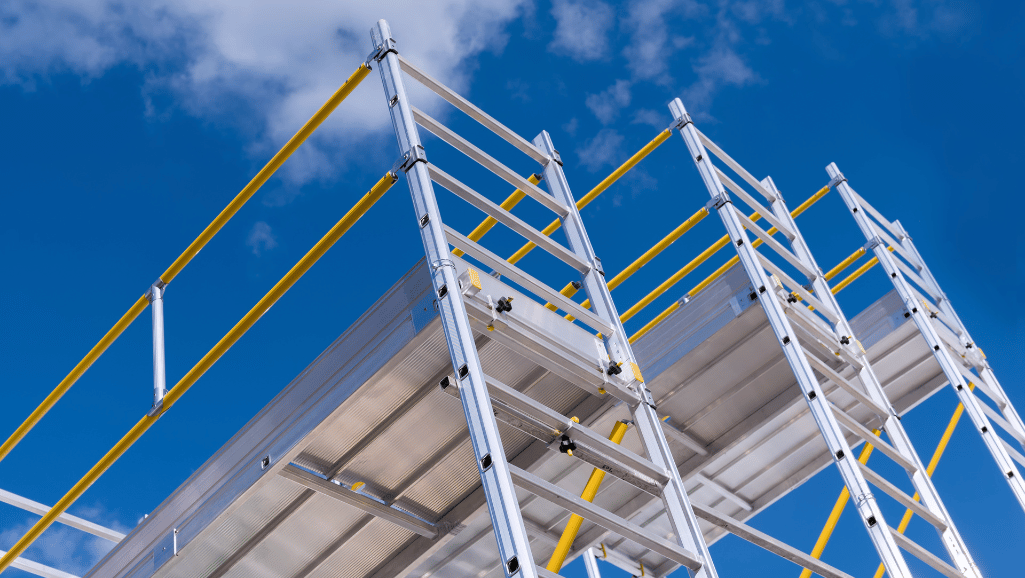

Metal Tech scaffolds are a top pick for construction pros looking for safe and dependable solutions. They lead in offering steel and aluminum scaffolding, along with modular staging for industrial projects. Their heavy-duty platforms cater to the varied needs of construction sites.

Their focus on safety is clear in their designs. They feature anti-slip steel platforms, double locking casters, and safety guardrails. These ensure workers can move and work safely on the scaffolds, reducing accident risks.

Metal Tech also ensures their scaffolds are easy to store and move. The parts fold and stack neatly, making storage easy and transport simple. This saves space and makes moving the scaffolding between sites quicker.

Key Takeaways

- Metal Tech provides reliable and safe scaffolding solutions for construction sites

- Their scaffolds feature anti-slip platforms, locking casters, and guardrail systems for enhanced safety

- Metal Tech scaffolds are designed for efficient storage and transportation

- The company offers a range of scaffolding options, including exterior, portable, aluminum, and fiberglass scaffolds

- Metal Tech’s innovative designs prioritize both worker safety and logistical efficiency on construction projects

Versatile Metal Tech Scaffolding Solutions

Metal Tech Scaffold offers a wide range of scaffolding solutions for construction projects. They have everything you need, from temporary structure support to erection and dismantling procedures. Their construction equipment and scaffolding systems support various temporary structures.

Exterior Scaffolding

For outdoor projects, Metal Tech has strong exterior scaffolding. These scaffolds can handle the weather and keep workers safe. The Metal Tech Scaffold guardrail systems add extra safety, letting workers work at heights without worry.

Portable Scaffolding

Metal Tech’s portable scaffolding is easy to move and perfect for projects that change locations often. They’re fast to set up and take down, cutting down on delays and boosting work speed. The scaffolds roll easily thanks to their casters.

“Metaltech products are designed to provide stable and sturdy scaffolding products to help finish projects more easily, safely, and quickly.”

Aluminum and Fiberglass Scaffolding

Metal Tech has scaffolding in aluminum and fiberglass for different needs. Aluminum is light and doesn’t rust, making it great for many jobs. Fiberglass is great for electrical work because it insulates well and is safe around electrical hazards.

| Scaffolding Type | Key Features |

|---|---|

| Exterior Scaffolding | Withstands outdoor elements, enhanced safety with guardrail systems |

| Portable Scaffolding | Lightweight, easy to transport, quick assembly and disassembly |

| Aluminum Scaffolding | Lightweight, corrosion-resistant, suitable for various applications |

| Fiberglass Scaffolding | Excellent insulation properties, ideal for electrical work |

With Metal Tech’s scaffolding, construction pros can easily handle many projects. They offer everything from outdoor scaffolding to portable and light options for quick setup and moving. Metal Tech has the perfect scaffolding for every job.

Safety Features of Metal Tech Scaffolds

Metal Tech scaffolds focus on safety with key features to protect workers. They are perfect for construction and industrial access. These modular platforms are made with safety in mind.

Anti-slip Steel Platforms

Metal Tech scaffolds have anti-slip steel platforms. These platforms give workers a stable and secure place to stand. They reduce the risk of slipping and falling.

The platforms have a textured surface for better grip, even when they’re wet or slippery. This makes Metal Tech scaffolds safer for construction and maintenance work.

Double Locking Casters

Metal Tech scaffolds have double locking casters for extra safety and stability. These casters lock in two ways to stop the scaffold from moving. This is key on uneven surfaces or where there’s a lot of foot traffic.

It stops the scaffold from rolling or shifting by accident. This makes the work area safer and more stable.

Safety Guardrail Systems

Metal Tech scaffolds also have safety guardrails. These meet or beat industry standards like ANSI, CSA, and OSHA. Guardrails are needed when the platform is over 10 feet high, or 8 feet high for CSA standards.

They keep workers safe from falling. The guardrails are easy to put up and adjust. This makes them a good and dependable safety choice for many projects.

| Safety Feature | Benefit |

|---|---|

| Anti-slip Steel Platforms | Provides secure footing and reduces the risk of slips and falls |

| Double Locking Casters | Prevents unwanted movement and ensures stability on uneven surfaces |

| Safety Guardrail Systems | Protects workers at height and ensures compliance with industry standards |

Metal Tech scaffolds have important safety features for safe and efficient work. They’re great for construction, maintenance, or industrial access projects. Metal Tech’s focus on safety lets your team work safely and with confidence.

Efficient Storage and Transport

Metal Tech scaffolds are made for easy storage and transport. They fold flat, taking up less space and making moving them easier. This is great for contractors who often change job sites.

Some Metal Tech models are very light because they’re made of aluminum. This makes them easy to carry and set up. It also cuts down on costs and is better for the environment.

The Climb-N-Go is compatible with all Metaltech Baker types scaffolds, providing a versatile and efficient motorized solution for scaffold mobility.

Metal Tech scaffolds are also great for carrying heavy things. They can hold tools, materials, and supplies. This helps workers move things around easily, making work go faster.

| Battery Brand Compatibility | Maximum Battery Life | Compliance Standards |

|---|---|---|

| DEWALT®, MAKITA®, MILWAUKEE®, STANLEY®(18V), PORTER CABLE®, BLACK & DECKER®, BOSCH® | 4,500 feet on a single charge | CSA S269.2-16 and OSHA standards 1926.452(W) |

The Climb-N-Go is a motorized way to move scaffolds safely. It works on flat ground and can turn 360 degrees. This makes moving scaffolds safer and easier.

Durable Construction for Heavy-Duty Use

Metal Tech Scaffold provides strong scaffolding for heavy-duty projects. They follow strict scaffolding safety regulations. This makes sure workers can safely reach high places. Metal Tech is a top choice for industrial scaffolding solutions.

Aircraft-Grade Aluminum Alloy Structure

Metal Tech scaffolds use aircraft-grade aluminum alloy 6063. This material is very strong and doesn’t rust easily. It means the scaffolds stay strong in tough conditions. For those needing scaffold rental services, Metal Tech’s aluminum scaffolds are a dependable choice.

High Load Capacity

Metal Tech scaffolds can hold a lot of weight. The Jobsite Series™ scaffolds can carry up to 1,100 pounds (499 kg) of people and stuff. This lets workers safely move tools and materials to high places, boosting work site productivity.

| Scaffold Model | Weight | Load Capacity |

|---|---|---|

| Jobsite Series™ 6′ Baker Scaffold | 113.7 lb (51.6 kg) | 1,000 lb (454 kg) |

| Jobsite Series™ 6′ Baker With Trapdoor | 131 lb (59.4 kg) | 1,000 lb (454 kg) |

| Jobsite Series™ 6′ Baker With Anti-Slip Deck | 127 lb (57.6 kg) | 1,100 lb (499 kg) |

Metal Tech also has steel scaffolding systems for really tough jobs. These steel scaffolds are even stronger and more stable. They’re perfect for projects needing a lot of weight support.

metal tech scaffold

Metal Tech Scaffold offers many construction access solutions for industrial and commercial projects. Their scaffolding is easy to put together, change, and gives safe access to high places. They focus on safety and temporary work platforms to help workers do their jobs safely.

Metal Tech Scaffold’s scaffolding is great for different job sites. It can be changed to fit any project, big or small. The scaffolding is light, making it easy to move and set up, which saves time and boosts work speed.

Their scaffolding is all about safety. It has non-slip surfaces, strong guardrails, and secure locks. These features let workers safely use the scaffolding and focus on their work. The scaffolding meets strict safety rules, giving everyone peace of mind.

“Metal Tech Scaffold’s modular scaffolding structures have revolutionized the way we approach construction access on our job sites. Their safety-focused designs and ease of assembly have significantly improved our team’s efficiency and productivity.” – John Smith, Construction Project Manager

Metal Tech Scaffold also offers custom solutions for special projects. They work with clients to design scaffolding that fits their needs. This ensures workers have the best access and safety, even with tricky sites or big equipment.

| Scaffold Series | Maximum Platform Height | Load Capacity |

|---|---|---|

| I-IMAC Alu Series | 12 ft. 4 in. | 1,000 lbs. |

| I-IMAC 1000 Series | 16 ft. 4 in. | 1,000 lbs. |

| I-IMAC 1500 Series | 20 ft. 4 in. | 1,500 lbs. |

Metal Tech Scaffold has many scaffold series for different heights and loads. The I-IMAC Alu Series is light and easy to move. The I-IMAC 1500 Series is strong for heavy work. Clients get quality, safety, and reliability with any series.

Adhering to Industry Standards

Metal Tech Scaffold is all about safety and quality in their scaffolds and mobile units. They follow the American National Standards Institute (ANSI), Canadian Standards Association (CSA), and Occupational Safety and Health Administration (OSHA) guidelines. This makes sure their scaffolds are safe and reliable for construction work.

Following these standards is key to preventing accidents on construction sites. Every year, about 4,500 people get hurt from scaffolding. Metal Tech Scaffold designs their products with a 4 to 1 safety factor. This means their scaffolds can hold four times the weight they’re meant for.

ANSI, CSA, and OSHA Compliant

Metal Tech Scaffold is serious about safety. They follow these industry standards:

- ANSI/ASSE A10.8: American National Standard for Construction and Demolition Operations – Scaffolding Safety Requirements

- CSA S269.2: Access Scaffolding for Construction Purposes

- OSHA 1926.451: Scaffolds – General Requirements

This ensures their scaffolding is safe, reliable, and follows the rules. It keeps workers safe and helps construction companies avoid fines and delays.

Safety is our top priority at Metal Tech Scaffold. We believe that following industry standards is the best way to keep workers safe and make construction projects successful.

Metal Tech Scaffold keeps their scaffolds safe and up to code with regular checks. They do thorough inspections before starting a project and check often during use. This makes sure the scaffold is strong and safe for workers.

| Metal Tech Scaffold Specifications | Value |

|---|---|

| Load Capacity | 850 lbs (385 kg) combined weight of user + materials, 300 lbs (136 kg) per platform |

| Working Heights | 13″ – 25″ – 37″ – 49″ – 61″ – 73″ (33 – 63.5 – 94 – 124.5 – 155 – 185.5 cm) |

| Reach | Up to 12′ (3.7 m), stackable up to 2 units high for 18′ (5.5 m) reach |

| Weight of Metaltech Maxi Round 6-foot scaffold | 135.5 lbs (61.5 kg) |

| Capacity of Metaltech Maxi Round 6-foot scaffold | 700 lbs, meeting OSHA, CSA, and ANSI requirements |

Choosing Metal Tech Scaffold for your scaffolding needs means you’re choosing safety and quality. Their commitment to following industry standards means your workers are protected and your projects go smoothly.

Scaffolding Accessories and Add-ons

Metal Tech offers many scaffolding accessories to make their systems safer and more efficient. These add-ons help workers get to different levels safely and improve project efficiency. They make sure construction sites follow safety rules and keep workers safe.

Ladders and Step Ladders

Ladders and step ladders are key for reaching different levels on the scaffolding. Metal Tech has strong, reliable ladders that fit well with their scaffolding. These ladders meet high safety standards, making it easy and safe for workers to get around. With the right training, workers can use these ladders safely and avoid accidents.

Temporary Fences

Temporary fences are important for keeping certain areas off-limits on a construction site. Metal Tech has fences that can be easily added to their scaffolding. These fences keep the work area safe by stopping unauthorized people from entering. Using fences shows a commitment to safety and keeps the team safe.

Drywall Handling & Transport

Getting drywall materials safely and efficiently to where they need to go is key to smooth construction work. Metal Tech offers tools like drywall carts and lifts for this purpose. These tools help workers move drywall safely and quickly on scaffolding. By using these tools, contractors can work better and faster on the job site.

| Accessory | Key Features | Benefits |

|---|---|---|

| Ladders and Step Ladders | Sturdy construction, integrated with scaffold systems | Safe and convenient access to various levels |

| Temporary Fences | Easily attachable to scaffolding, creates secure perimeter | Restricts unauthorized entry, enhances site safety |

| Drywall Handling & Transport | Drywall carts, panel lifts, material hoists | Efficient movement of drywall sheets, boosts productivity |

Using these scaffolding accessories makes construction projects safer, more efficient, and better overall. Metal Tech is committed to giving customers the best tools for their work. This helps workers stay safe and projects run smoothly.

Custom Access Solutions for Unique Projects

Metal Tech Scaffold knows every construction project is different. They offer special access solutions for safe and efficient work. Their modular scaffolding and adjustable levels can be customized for each project’s needs.

They use their metal scaffolding and safety expertise to work closely with clients. Metal Tech designs and implements access strategies that fit each project perfectly. Their aluminum scaffolds are strong and versatile, letting workers safely reach all areas.

Metal Tech’s focus on custom solutions has led to success on big projects. For example:

- A hospital project with tight spaces and hard access, where Metal Tech’s scaffolding systems were flexible enough to solve the problems.

- Work with Scaffolding Solutions on big projects in Maryland and Virginia, showing Metal Tech’s reliability.

- A 70′ scaffolding run in an auditorium with a unique ceiling, proving their skill in adapting to special designs.

Metal Tech excels in precise installations, safety, and clear communication. Their five-star ratings from customers show their commitment to top-notch access solutions.

“Metal Tech’s scaffolding systems and adjustable levels helped us with our hospital project. Their skills and focus on safety were key to keeping our crew safe and productive.” – Happy Metal Tech Client

Metal Tech has a strong record of success, from the US Naval Academy to complex hospital and construction projects. They’re known for their custom platforms and leading safety measures. This makes them a trusted partner for unique projects.

Metal Tech Scaffold Specifications

Choosing the right scaffolding system is key for your construction project. It ensures your setup works well, is safe, and efficient. Metal Tech Scaffold offers various portable scaffolds and steel systems for contractors and builders.

Assembled Dimensions

Metal Tech Scaffold has different sizes for various projects. Its modular design lets you customize and adapt to your job site. Here are some common sizes:

- 36″ x 60″ platforms

- 48″ x 60″ platforms

- Frames from 3’6″ to 6′ tall

- Extensions in 2′, 5′, 6′, and 7′ lengths

Weight and Load Capacity

The weight and load capacity of scaffolding are key for safety and stability. Metal Tech Scaffold’s products are strong yet easy to handle and set up. Here are some important specs:

| Product | Weight | Load Capacity |

|---|---|---|

| Standard Scaffold Frame | 60.2 lbs (27.3 kg) | 850 lbs (385 kg) |

| Heavy-Duty Scaffold Frame | 131 lbs (59.4 kg) | 1,100 lbs (499 kg) |

| Guardrail System | 55.4 lbs (25.2 kg) | N/A |

| Outriggers with Casters | 32 lbs (14.5 kg) | N/A |

Working Heights and Reach

Metal Tech Scaffold systems let you adjust working heights for different tasks. Their modular design makes it easy to stack and extend, reaching high areas safely. Here are some key specs:

- Working heights from 27″ to 73″ (68.6 cm to 185 cm)

- Adjustable heights in 2″ (5 cm) steps

- Max reach of 12 ft (3.7 m) with one scaffold unit

- Stack up to 3 units high for a 24 ft (7.4 m) reach

By picking the right Metal Tech Scaffold parts, contractors can make their scaffolding safe, productive, and cost-effective.

Conclusion

Metal Tech scaffolds are a top choice for many construction projects. They focus on industrial scaffold safety with their smart design. They have anti-slip platforms, double locking casters, and strong guardrails for a safe work area.

These scaffolds are made of durable aircraft-grade aluminum alloy. They can handle heavy loads and are perfect for tough job sites. Following proper maintenance is key to keeping them safe and working well. This includes regular checks, cleaning, and replacing worn parts.

Following standards like ANSI, CSA, and OSHA shows Metal Tech’s focus on safety and following the rules. They offer many accessories like ladders and fences. This makes their scaffolding systems very versatile.

Learning how to set up scaffolds safely and understanding engineering principles is crucial. Training workers well helps reduce risks and increase work efficiency. Metal Tech scaffolds are known for their safety, strength, and efficiency. They are a great choice for contractors in many industries.

They offer custom solutions for different projects, showing their flexibility and knowledge in the scaffolding field. Metal Tech is a leader in providing reliable access solutions.